Professional wire drawing dies manufacturer

The company offers direct sales, ensuring high-quality products and services with a strong commitment to business integrity and extensive production experience.

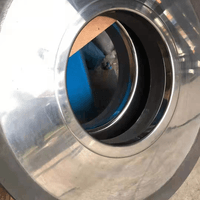

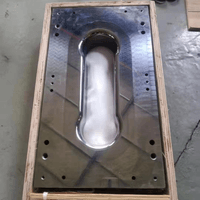

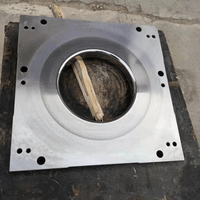

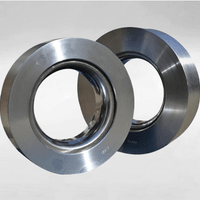

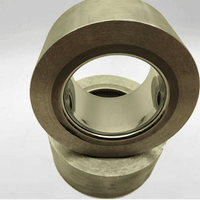

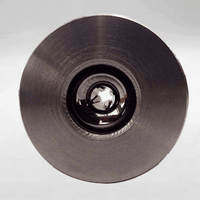

STRETCH MOLD

STRETCH MOLD it is suitable for all walks of life and has wide practicability, it is a more common process in the stamping process. From blank to stretch forming, it takes multiple steps to complete, primary stretching → secondary stretching →...... → Molding. Die in the process of stretching will produce a variety of problems, common problems such as: wrinkling, top R strain, side wall strain, product surface strain, tensile height is too high or too short, etc... A series of questions. So the drawing process is also a difficulty in the stamping die.

The following describes the general characteristics of the drawing mold:

First, stretching concept:

1. Stretching: press the sheet material into a hollow part (the wall thickness is basically unchanged).

2. Stretching process: It is transferred from the material on the plane (flange) to the barrel (box) side wall, so the overall size of the plane changes greatly.

3. Tensile coefficient: the ratio of tensile diameter to the diameter of the embryo "m" (the deformation degree of the embryo to the workpiece).

Drawing die introduction and characteristics

Second, the main factors affecting the tensile coefficient:

1. Mechanical properties of materials (yielding strength -- elastic deformation; Tensile strength ---- plastic deformation; Elongation coefficient; Section shrinkage).

2. Relative thickness of the material.

3. Number of stretches.

4. Stretching style.

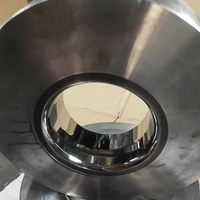

5. Radius of the corners of the convex and concave die.

6. Stretch working surface finish and lubrication conditions, clearance, etc.

7. Stretch speed.

Third, drawing process arrangement:

1. Parts with thinner tensile depth than diameter: reduce the cylinder diameter to increase the height, and the radius of the rounded corner can be gradually smaller.

2. Parts with thicker tensile depth and similar diameter: the corner radius can be reduced in the process of maintaining the same height and gradually reducing the cylinder diameter.

3. The flange is very large and the circle radius is very small: it should be achieved by multiple shaping.

4. When the flange is too large: if necessary, it should be expanded and formed.

Drawing die introduction and characteristics

In order to reflect the principle of "flange unchanged", so that the flange formed by the first stretch does not participate in the subsequent stretch deformation, the material of the wide flange stretch reducing the first time into the die (that is, the material forming the wall and the bottom) should be 3 to 10% more than the actual material required for the final stretch.

Note: The upper limit is taken when the number of drawing times is calculated according to the area, and the lower limit is taken on the contrary. This excess material will be returned to the flange at each subsequent stretch cut, causing the flange to become thicker but avoiding head pulling, and the local thinning area can be corrected by shaping. Therefore, it is very important to strictly control the height of each stretch.

Four, box stretching

The corner part is equivalent to the drawing of the cylindrical part, and the straight wall part is equivalent to the bending deformation.

Five, stretch lubrication

In the stretching process, there is friction between the material and the mold, so there must be a special stamping and stretching lubricating oil, large friction not only increases the tensile coefficient, the tensile force will increase and wear, scratching the mold and the workshop surface is harmful. Therefore, using lubrication conditions to exert the deformation potential of the force transfer zone to compensate for the non-uniformity can not only improve the bearing capacity of the force transfer zone, but also promote the smooth plastic deformation of the whole deformation zone. Therefore, lubrication conditions are necessary in the drawing.