Professional wire drawing dies manufacturer

The company offers direct sales, ensuring high-quality products and services with a strong commitment to business integrity and extensive production experience.

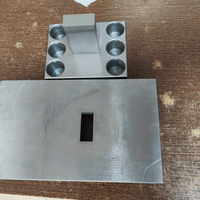

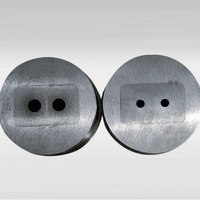

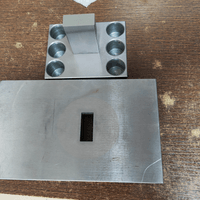

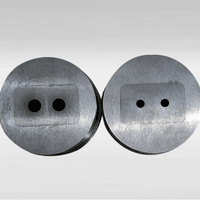

COPPER EXTRUSION ACCESSORIES

Powder metallurgy die

Metal powder injection molding is a new technology which combines traditional powder metallurgy technology with plastic injection molding technology. It is a revolution in the forming process of small complex parts. The suitable technical powder and adhesive are evenly mixed into a rheological feed, which is injected into the injection machine, and the blank obtained is sintered and densified into a finished product after degreasing treatment, and can be post-treated if necessary.

Metal powder injection molding combines the advantages of powder metallurgy and plastic injection molding technology, breaking through the limitations of traditional metal powder molding process in product shape. At the same time, the use of plastic injection molding technology can produce parts with complex shapes in large quantities and high efficiency: such as various external grooves, external threads, conical external surfaces, cross through holes, blind holes, concave tables, key pins, reinforced plates, surface knurls, etc.

The production process is as follows: batching → mixing → granulation → injection molding → chemical extraction → high temperature debonding → sintering → post-treatment → finished product