Provide you with excellent equipment solutions

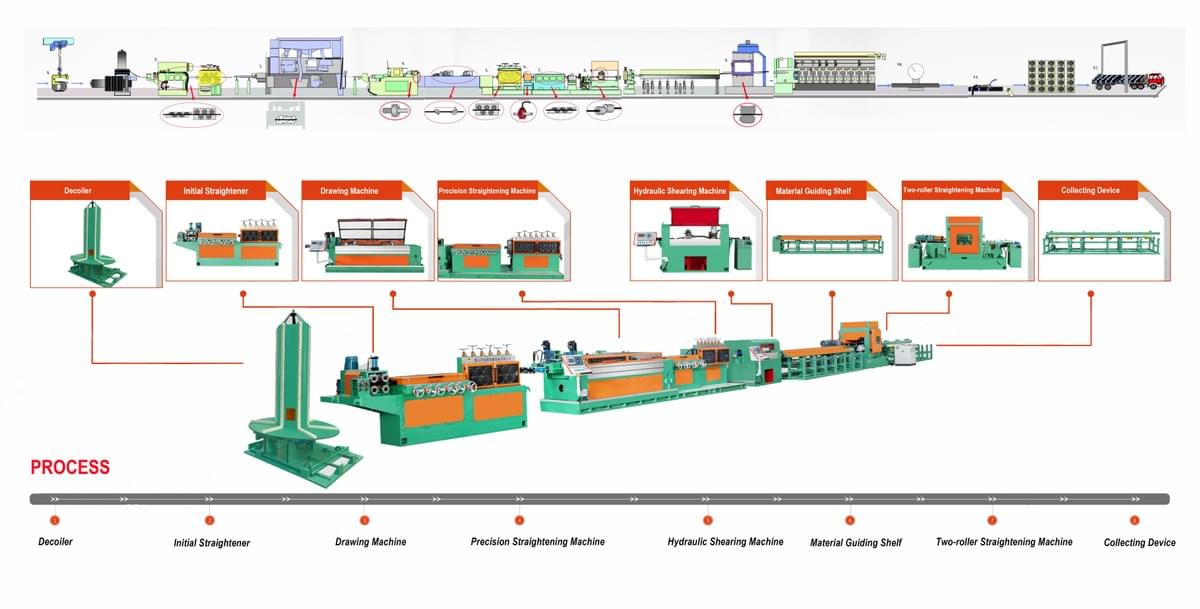

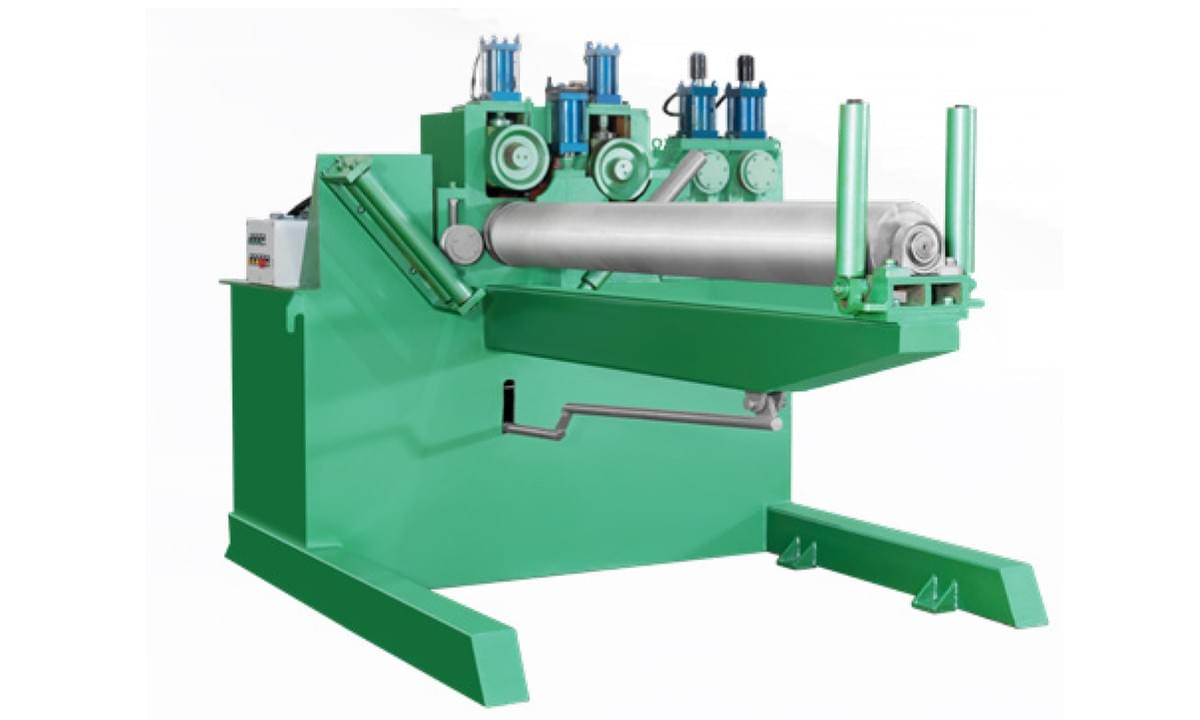

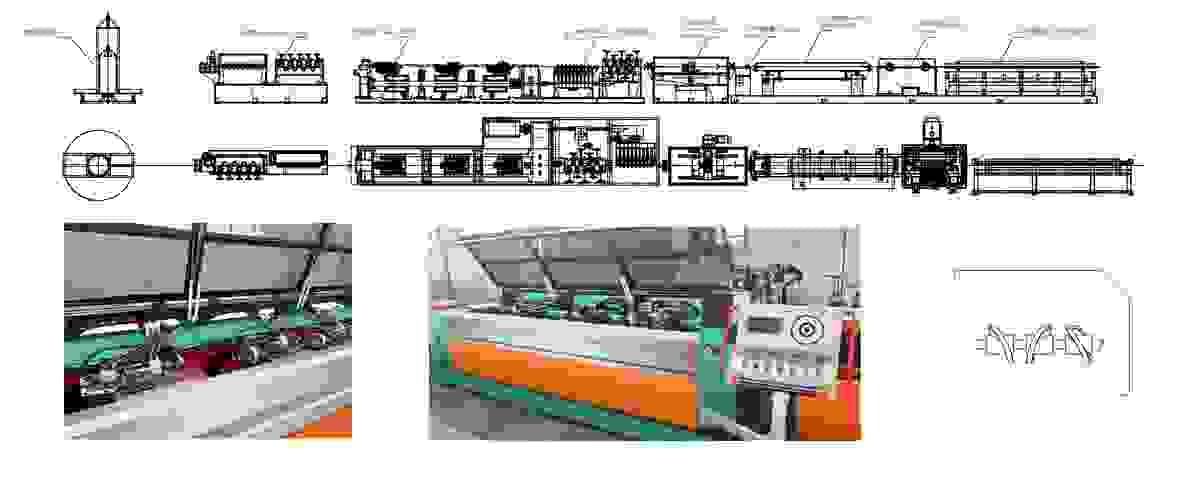

The combined continuous drawing unit is a special equipment that can produce cold-drawn profiles of different shapes and specifications.It is a combined unit that integrates the processes of billet opening, initial straightening,drawing and finished product straightening,fixed-length shearing,polishing,and collection.

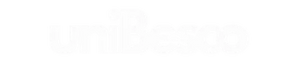

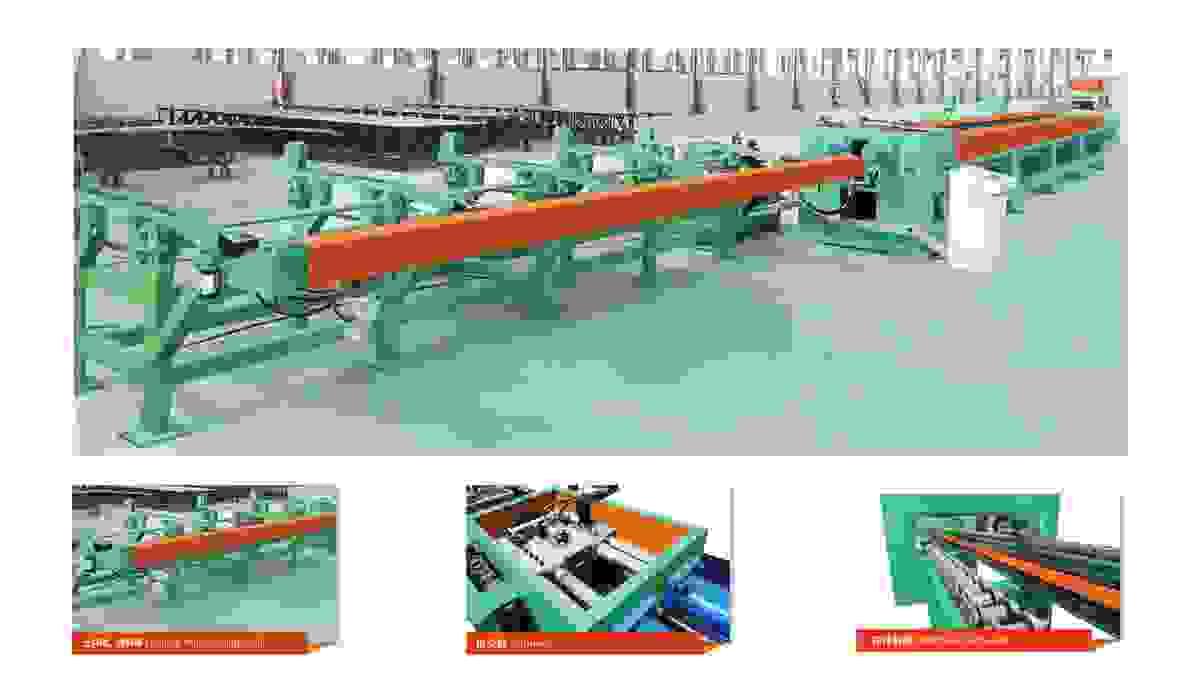

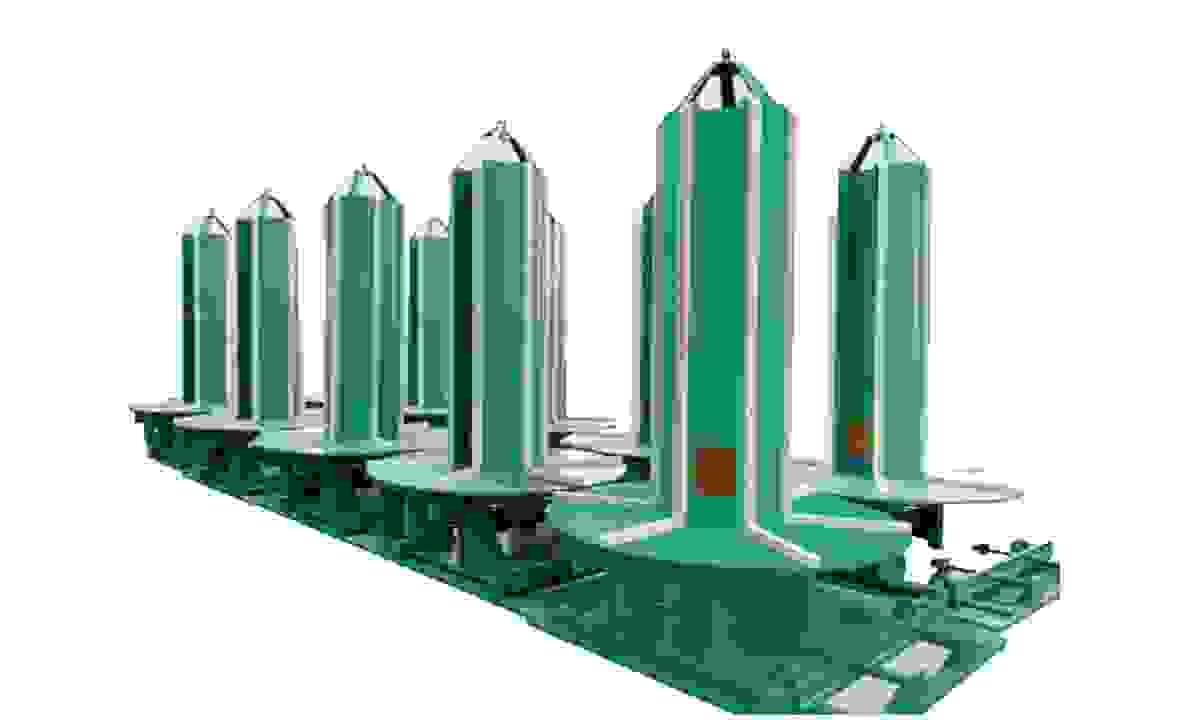

Combined drawing unit production line

The combined continuous drawing unit is a special equipment that can produce cold-drawn profiles of different shapes and specifications. It is a combined unit that integrates the processes of billet opening, initial straightening, drawing and finished product straightening, fixed-length shearing, polishing, and collection.

LHJZ continuous drawing unit is a high-efficiency, professional processing equipment for metal bars and pipelines. The unit has the functions of uncoiling, initial straightening, stretching, fine straightening, cutting to length, feeding, polishing, and collection of finished products. It can process multiple processes in one, and can process a variety of special-shaped materials, such as hexagonal, square, flat square, round and other profiles. The stretching mechanism of this unit can also be divided into double cam or triple cam structure. The triple cam structure is that the stretching mechanism has three drawing trolleys that run alternately during stretching. Longer life.

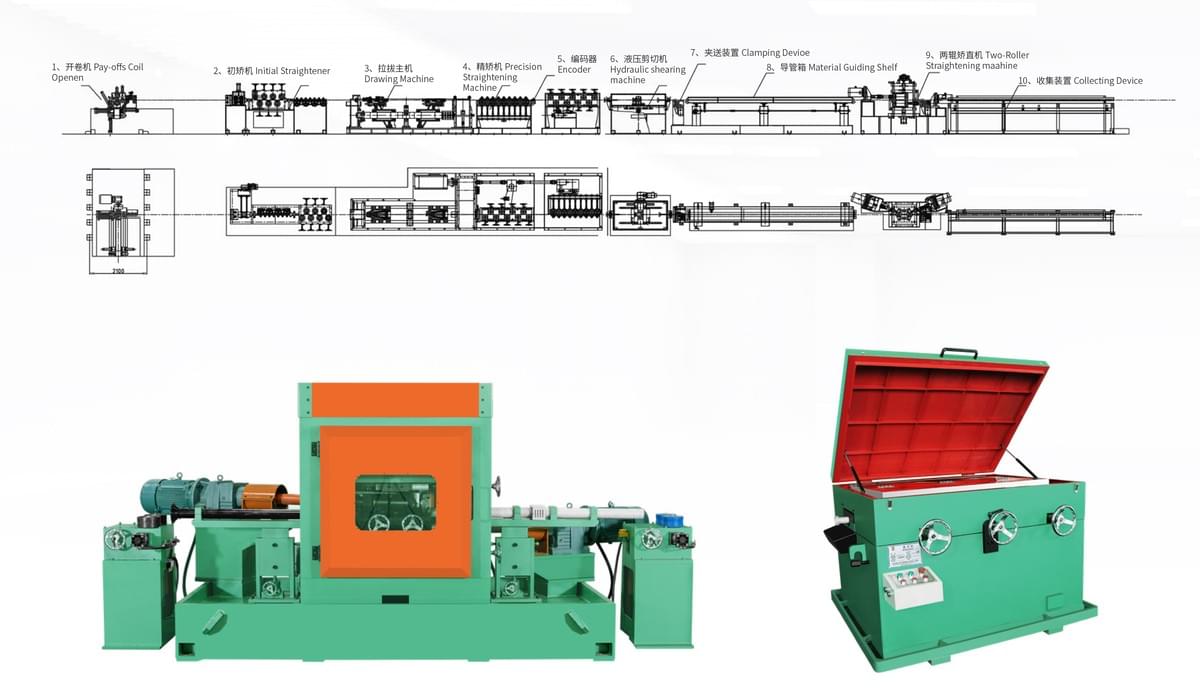

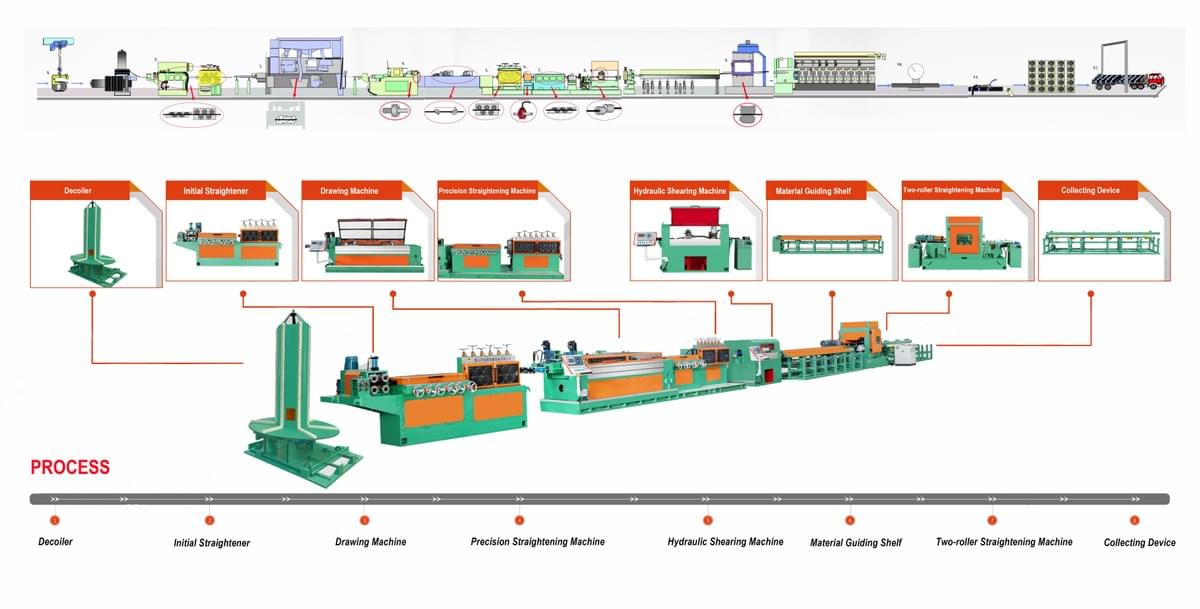

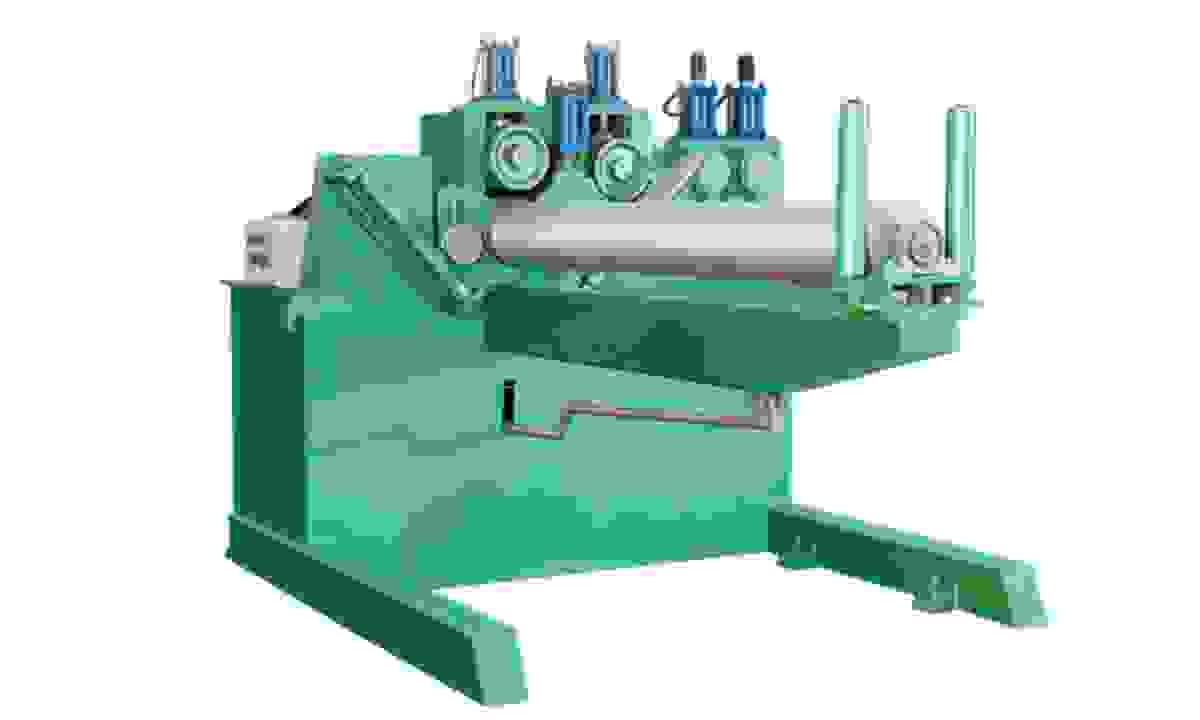

Combined drawing machine (CNC hydraulic shear)

The combined continuous drawing unit is a special equipment that can produce cold-drawn profiles of different shapes and specifications. It is a combined unit that integrates the processes of billet opening, initial straightening, drawing and finished product straightening, fixed-length shearing, polishing, and collection.

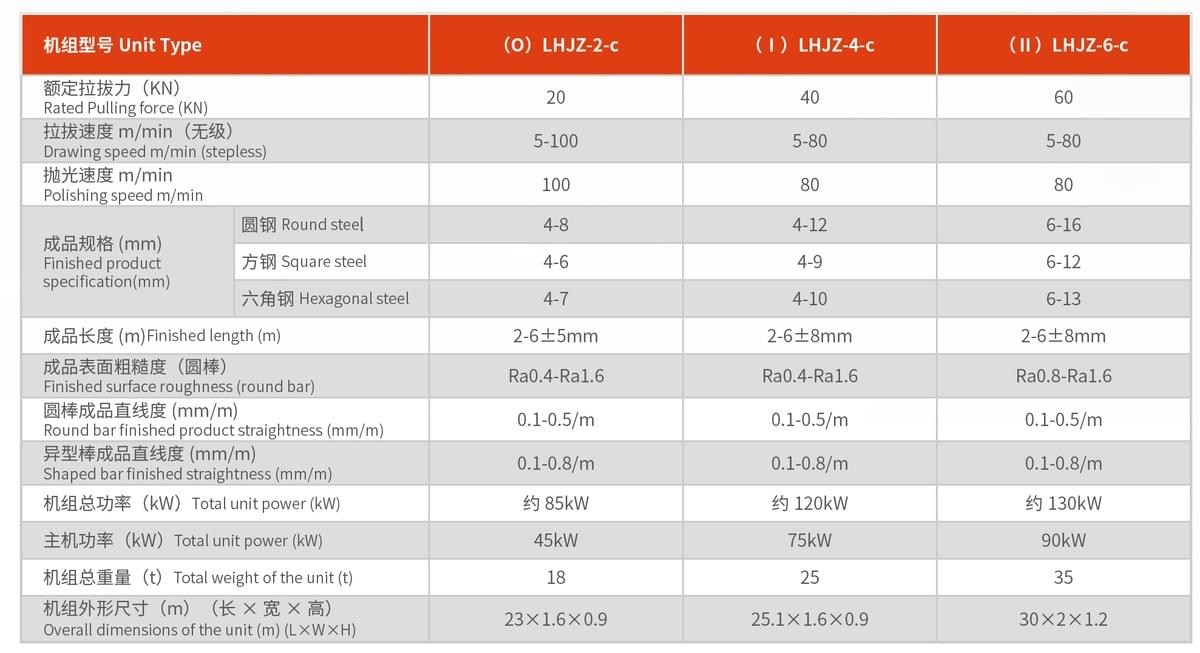

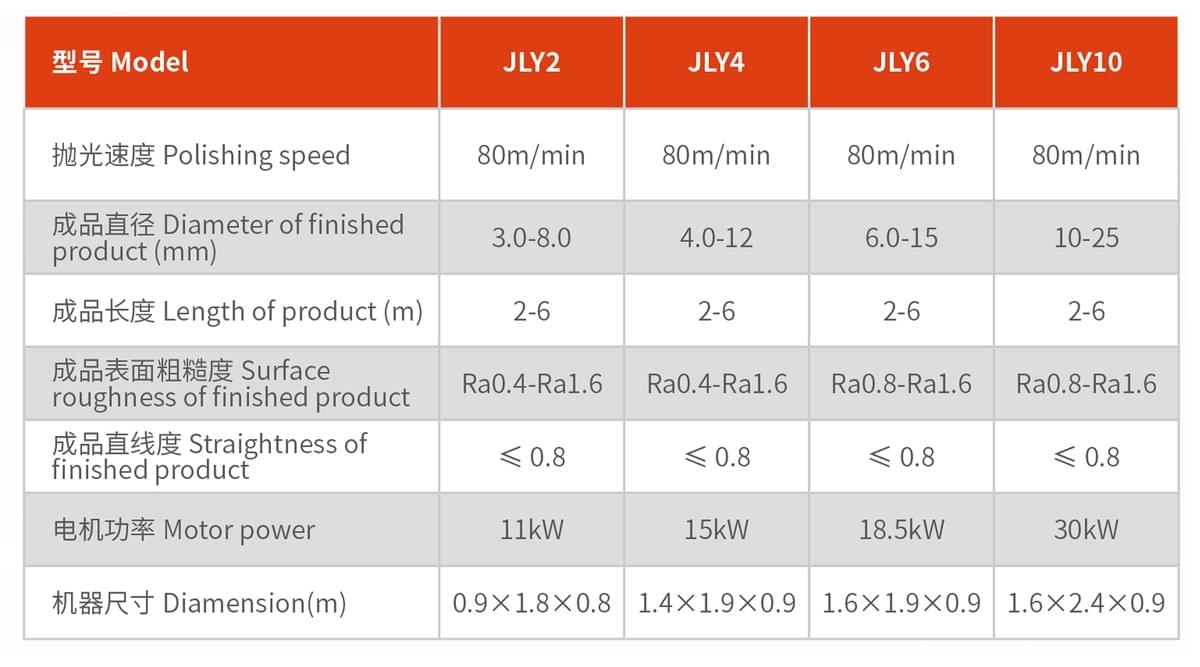

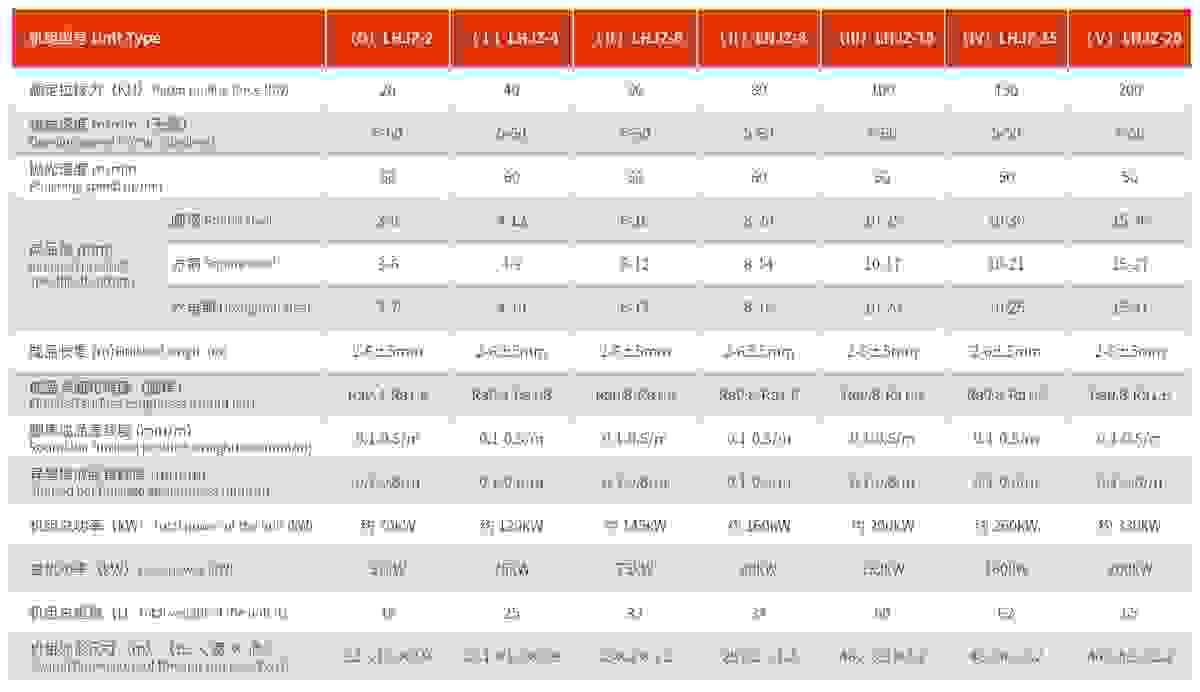

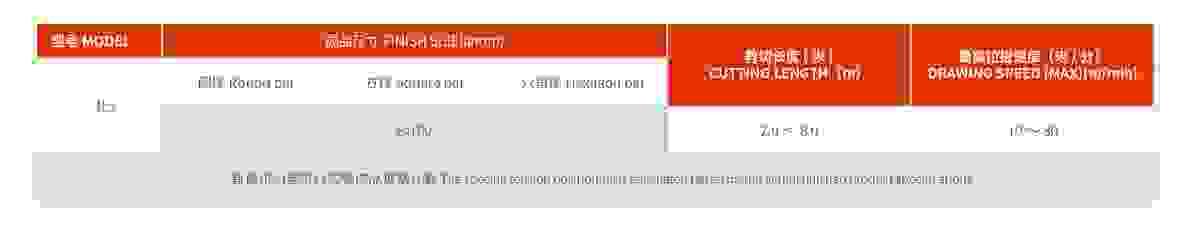

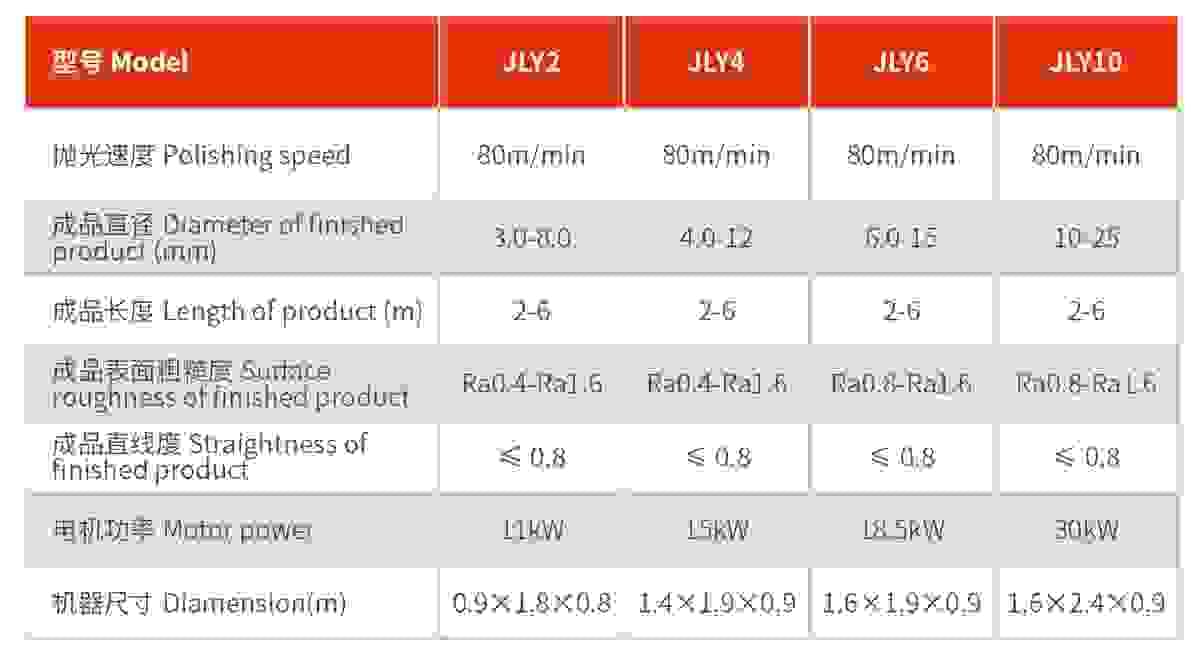

TECHNICAL PARAMETER

The combined continuous drawing unit is a special equipment that can produce cold-drawn profiles of different shapes and specifications. It is a combined unit that integrates the processes of billet opening, initial straightening, drawing and finished product straightening, fixed-length shearing, polishing, and collection.

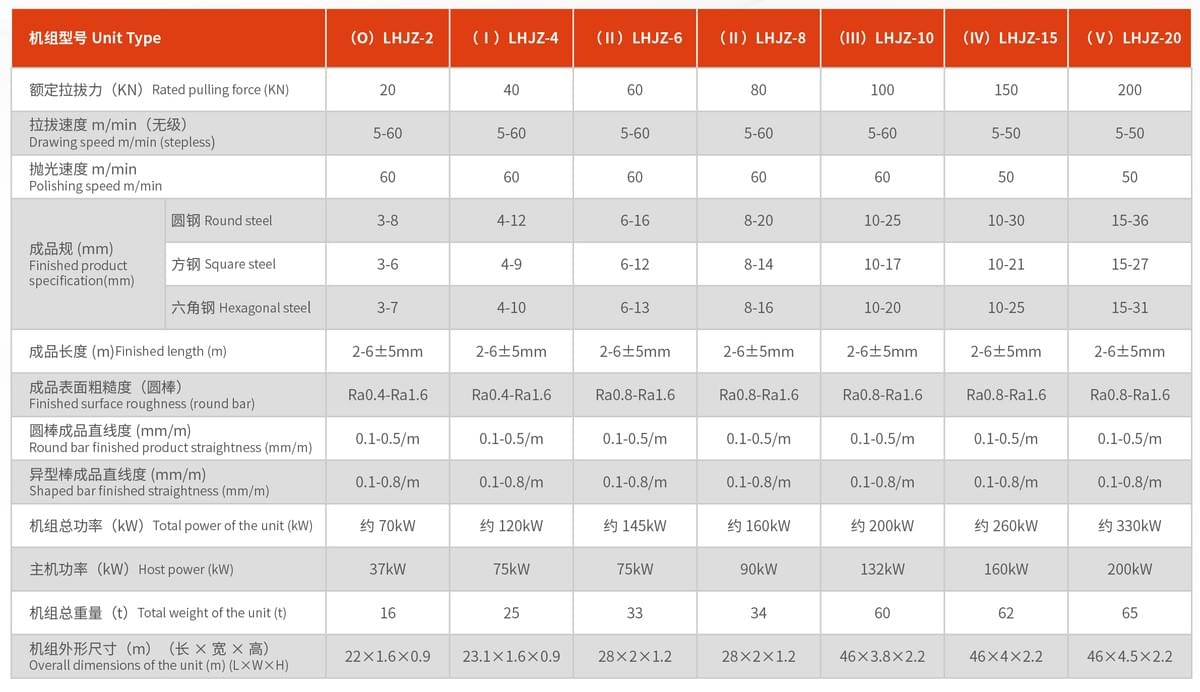

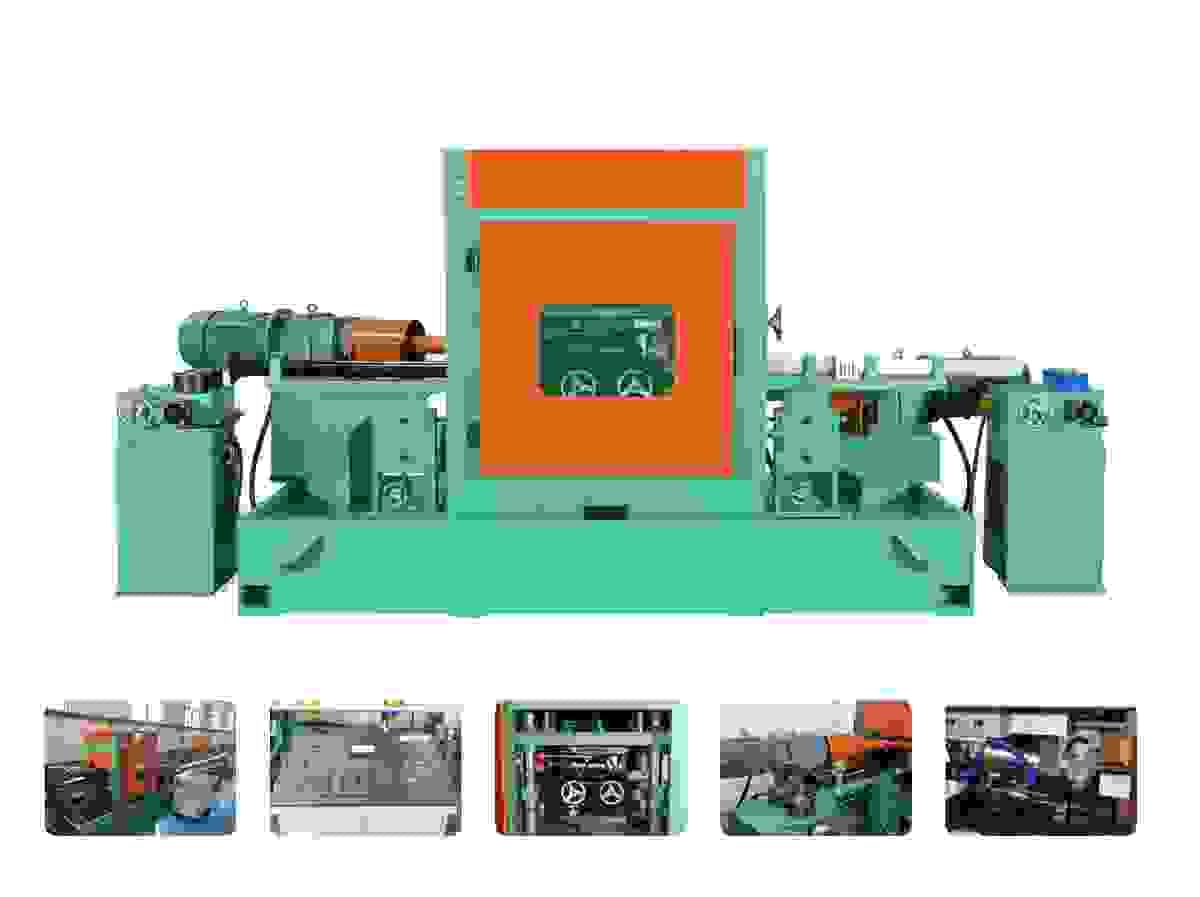

Combined Drawing Machine (three cam CNC hydraulic shears)

Combined continuous drawing unit is capable of producingdifferent shapes, a variety of cold-drawn profile specificationsof special equipment. Is a set of

open blank volume, initialstraightening, drawn and finished fine straightening, fixedlength cutting, polishing, collecting and other processes inone combined unit.This unit has three sets in tension whenpulling the car run alternately.

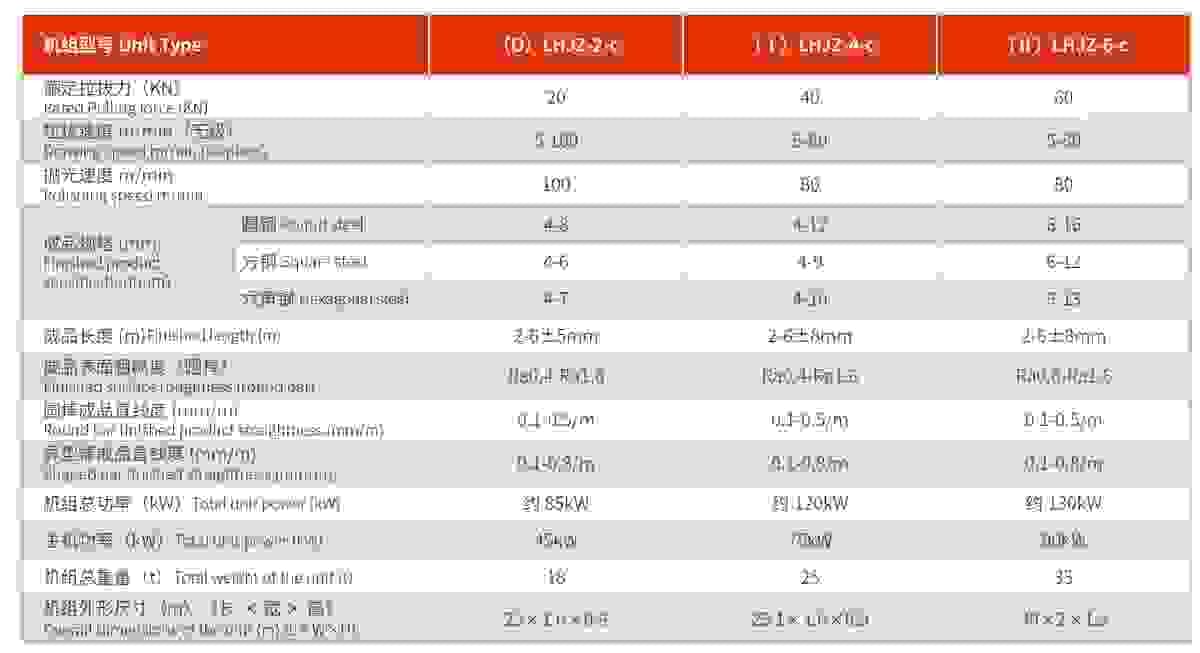

TECHNICAL PARAMETER

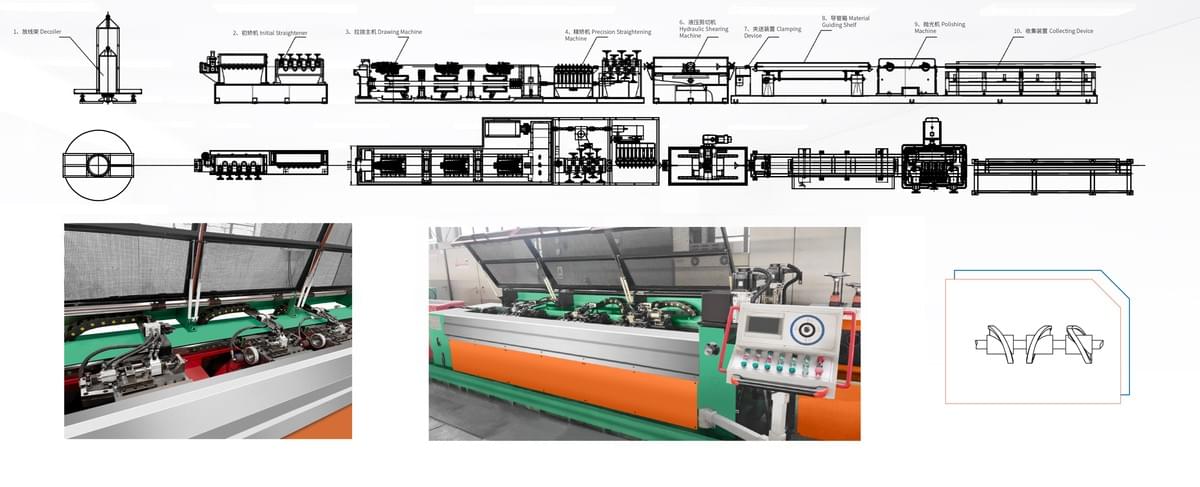

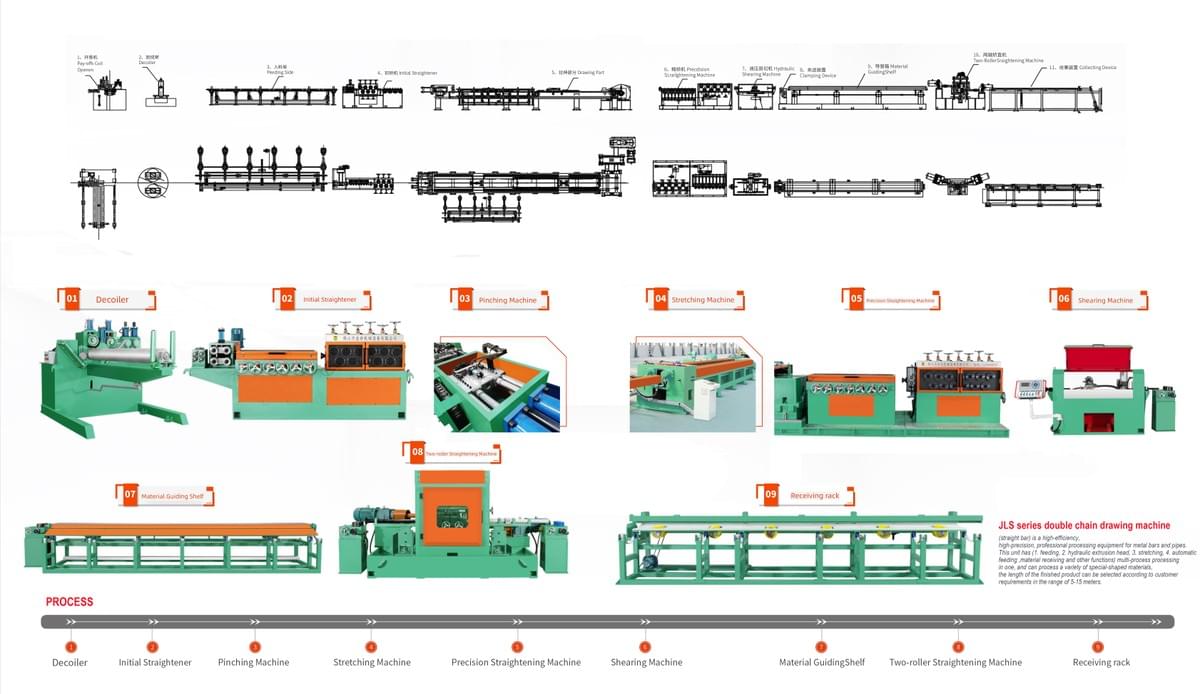

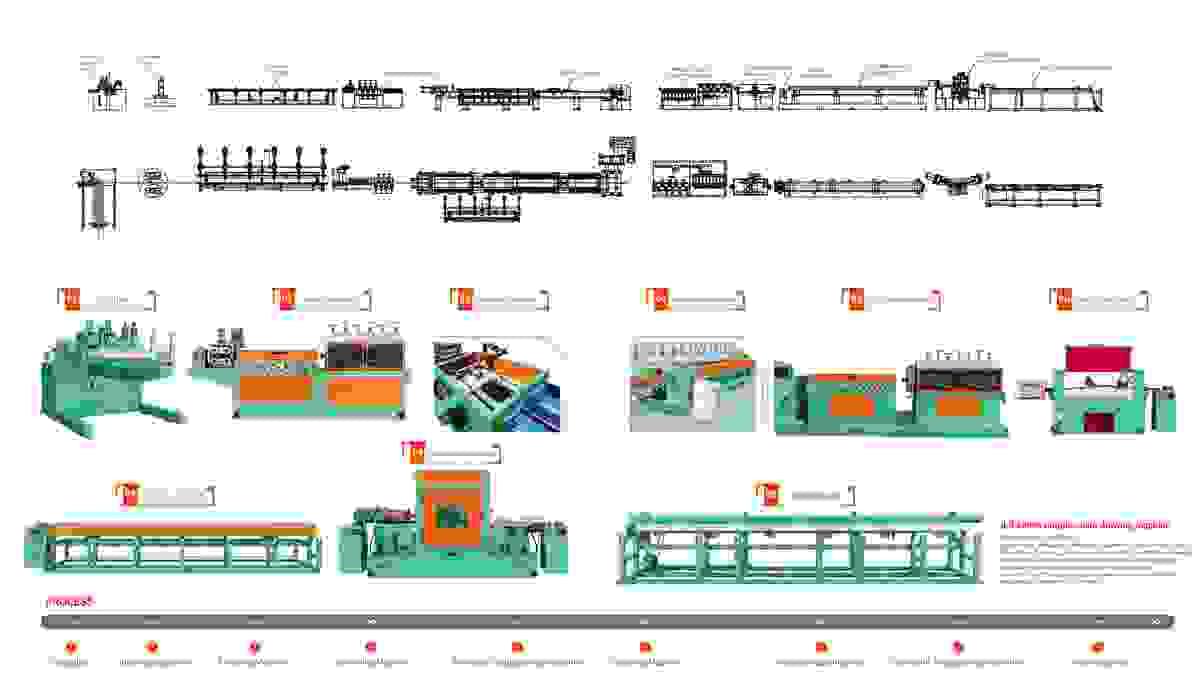

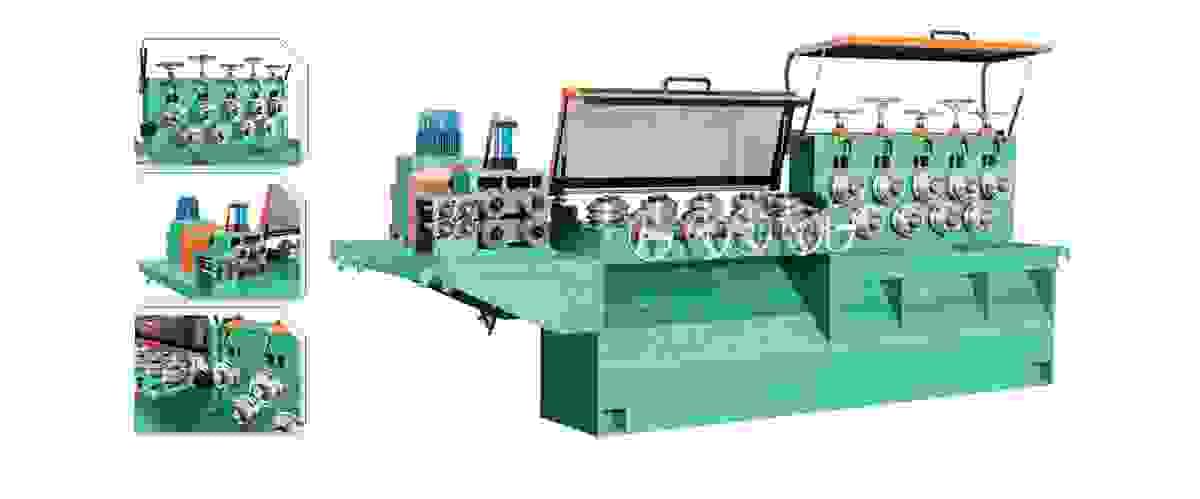

Double Chain drawing unit

Double chain double drawing machine is a high-efficiency, high-precision, professional processing equipment for metal rods and pipes. This unit has the functions of feeding, hydraulic extrusion, stretching, straightening, Fixed length cutting, polishing, finished product aggregate and other functions, and can process a variety of special-shaped materials, the length of the finished product can be selected according to customer requirements in the range of 5-15 meters. And this machine can also be divided into a group of drawing trolleys and two groups of drawing trolley structures. The two groups of drawing trolley structures can alternately draw metal wires, which can achieve high-speed continuous drawing and more stable performance.

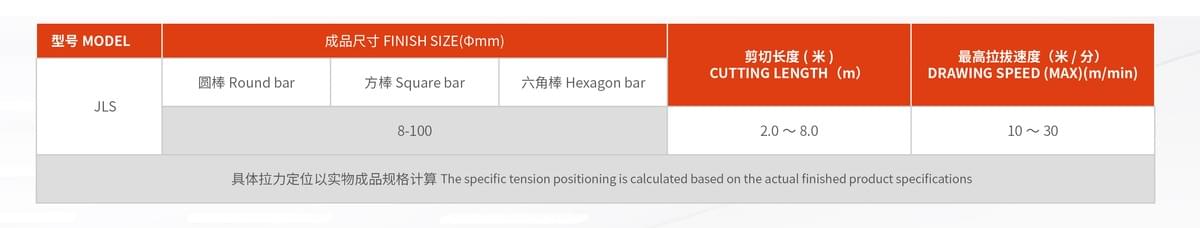

TECHNICAL PARAMETER

Double chain double drawing machine is a high-efficiency, high-precision, professional processing equipment for metal rods and pipes. This unit has the functions of feeding, hydraulic extrusion, stretching, straightening, Fixed length cutting, polishing, finished product aggregate and other functions, and can process a variety of special-shaped materials, the length of the finished product can be selected according to customer requirements in the range of 5-15 meters. And this machine can also be divided into a group of drawing trolleys and two groups of drawing trolley structures. The two groups of drawing trolley structures can alternately draw metal wires, which can achieve high-speed continuous drawing and more stable performance.

Duplexes drawing machine (straight bars)

JLS series double chain drawing machine (straight bar) is a high-efficiency, high-precision, professional processing equipment for metal bars and pipes. This unit has (1. feeding, 2. hydraulic extrusion head, 3. stretching, 4. automatic feeding , material receiving and other functions) multi-process processing in one, and can process a variety of special-shaped materials, the length of the finished product can be selected according to customer requirements in the range of 5-15 meters.

Two-roller Straightening Machine

This unit is an integral part of the combined drawing machine, mainly used for straightening the bar, with the advantages of high precision and high speed. It is driven by two motors independently, and drives the universal coupling and the main drive shaft to rotate after frequency conversion, and the rollers mounted on the main drive shaft also rotate at the same time.

The center height of the vertical two-roller is adjustable. When the wire diameter of the finished product changes, the two rollers should be parallel adjusted to a position slightly larger than the specification of the material to be processed.

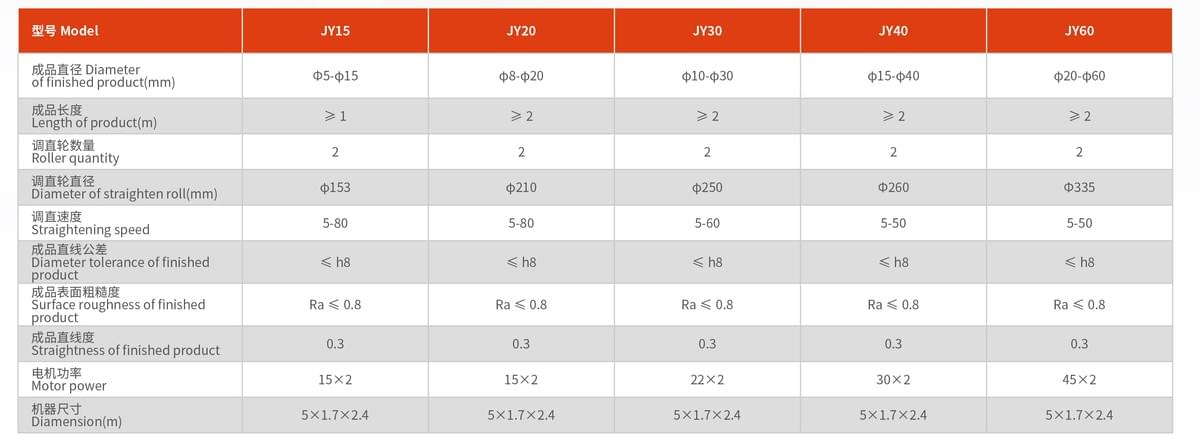

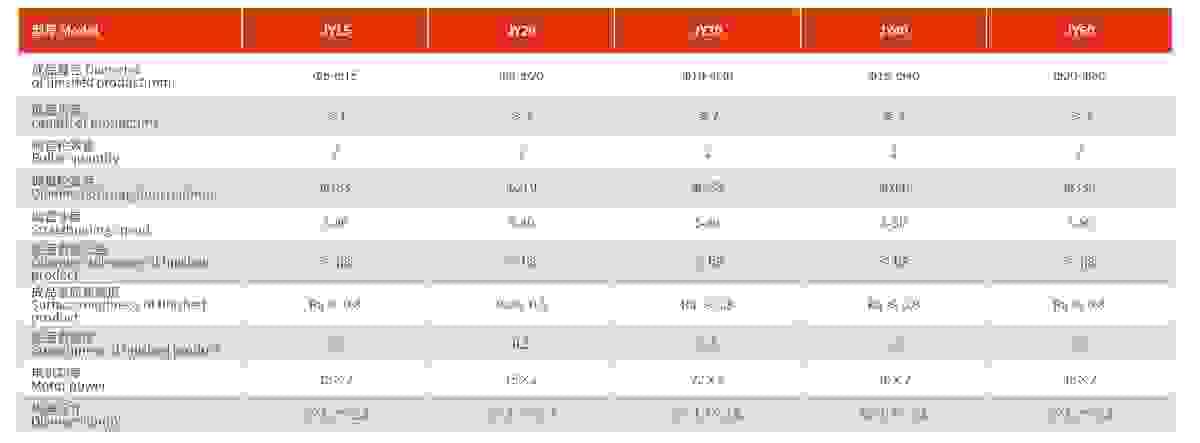

TECHNICAL PARAMETER

Round bar polishing machine

This unit is an integral part of the combined drawing machine, which is used to polish the straightened round bars. It is driven by a motor alone, and is transmitted to the reduction box through the coupling, and then to the left and right two fixed polishing discs to make them rotate. to drive the adjustable polishing disc to rotate.

TECHNICAL PARAMETER

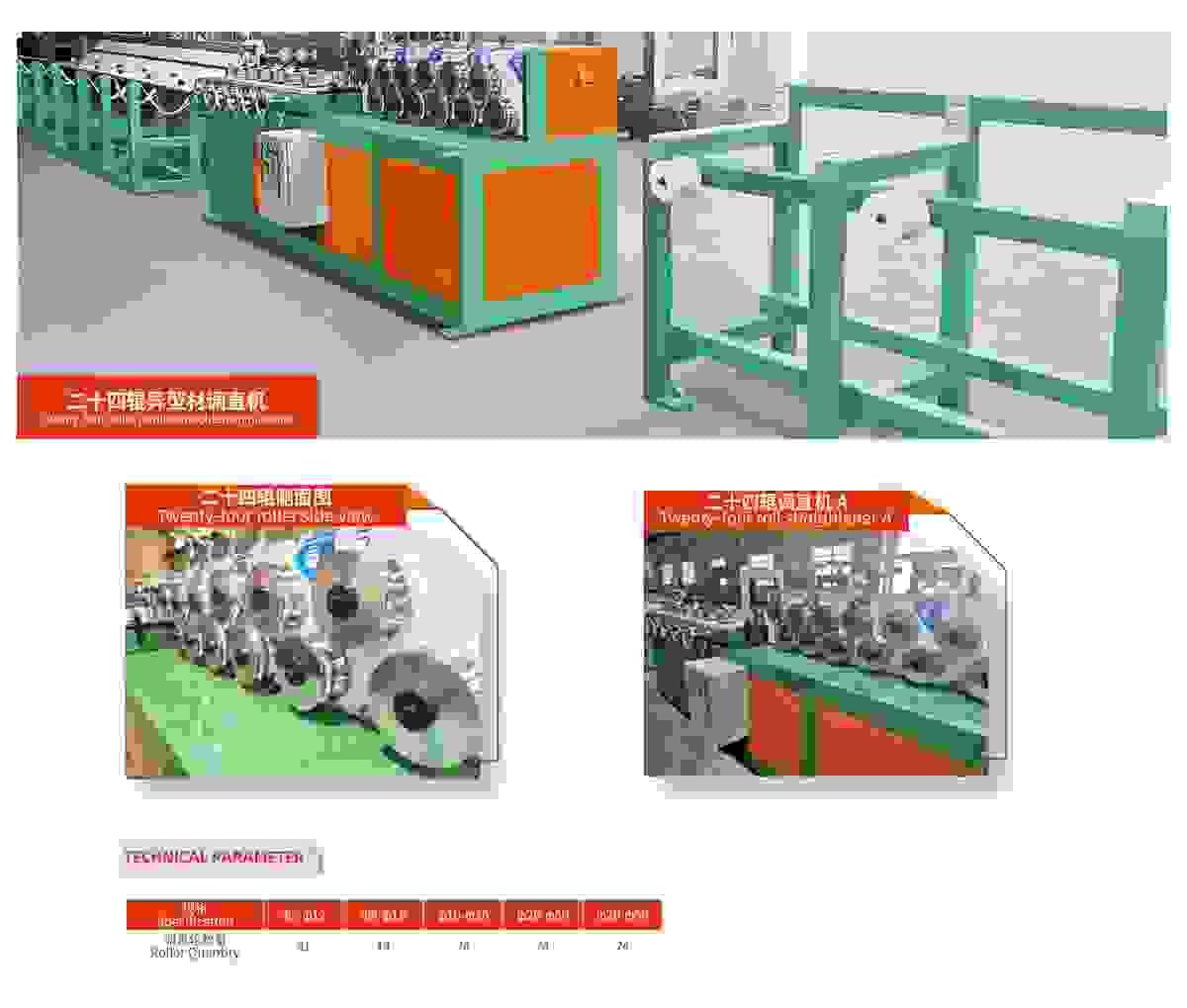

Profile straightening machine

High-speed special-shaped straightening machine is suitable for straightening round, square,

hexagonal or other special-shaped materials. This unit has the advantages of high speed, high precision,

easy operation and easy maintenance.

Pre-straightening machine

Pre-straightening machine is a device for preliminary straightening of metal profiles, bars, pipes, wires, etc. The pre-straightening machine changes the straightness by pressing the bar or the like through the straightening roller. It consists of a pinch device, a horizontal inversion and a vertical device.

Principle of straightening machine: The bending part of the steel is subjected to considerable reverse bending or stretching, so that a certain elastic-plastic deformation occurs in this part. When the external force is removed, the steel undergoes elastic recovery and then reaches straightness.

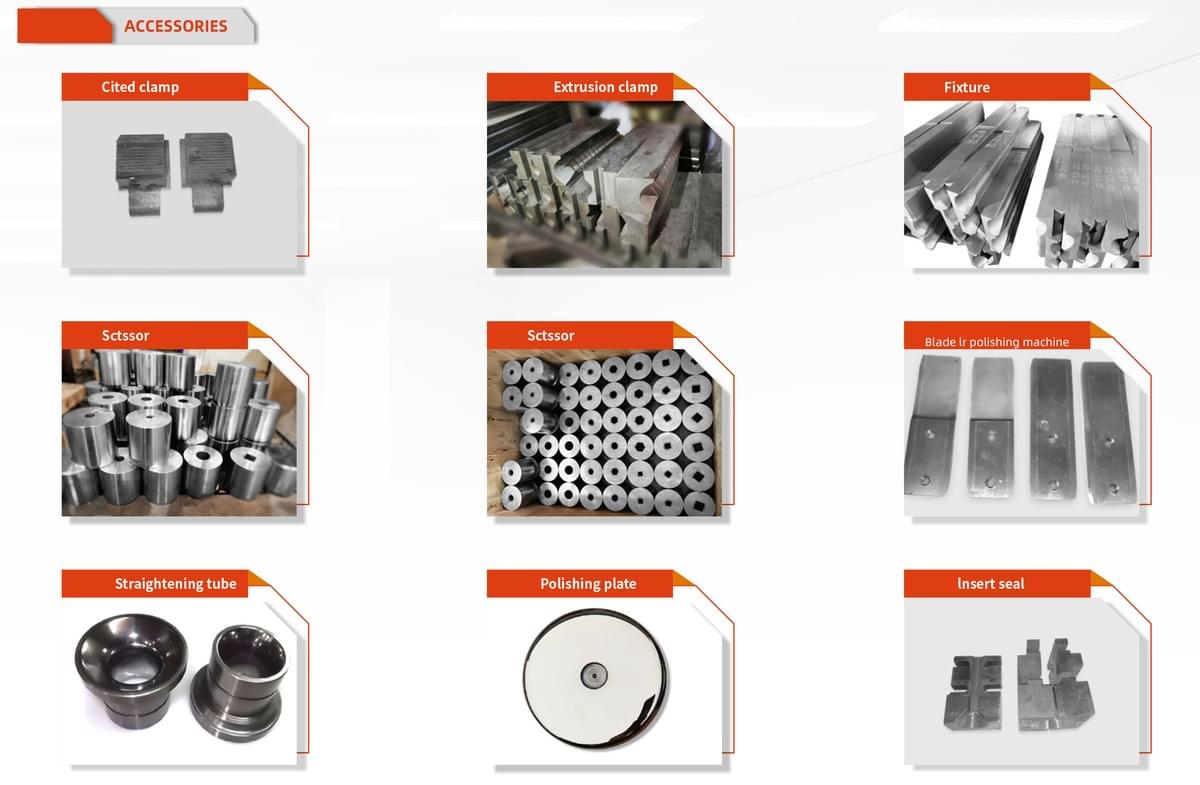

ACCESSORIES

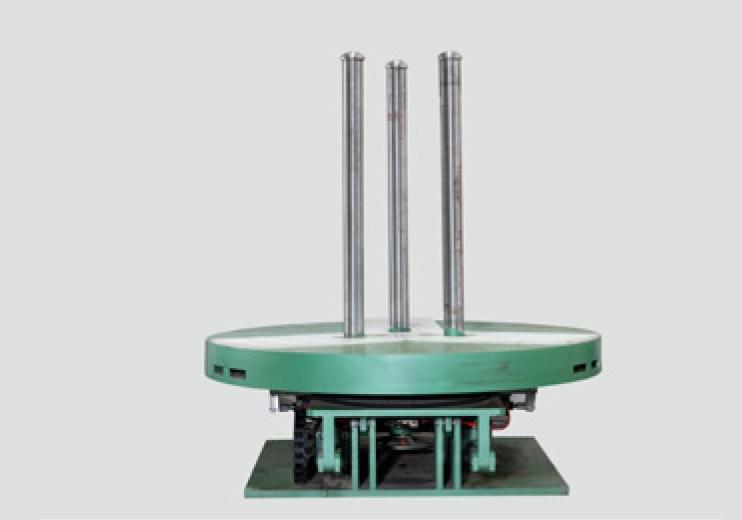

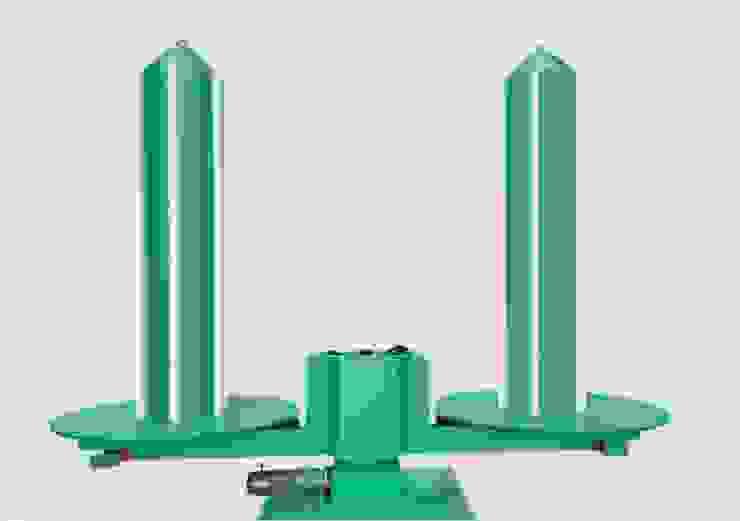

Decoiler

The pay-off reel is a metal structure frame for placing blank coils.

Decoiler

The pay-off reel is a metal structure frame for placing blank coils. The standard pay-off reel is mainly composed of a pay-off reel base and two material frames. When the equipment is running and the coiled material in the pay-off rack is finished, the empty material frame can be hoisted from the pay-off base with a hoist, and the other material frame loaded with the coiled material continues to be hoisted to the pay-off base. Use alternately. Reduce the waiting time for loading.

Hydraulic dumping and pay-off stand

The hydraulic dumping and pay-off reel is a metal structure frame for laying blank coils. The

90-degree loading can be automatically dumped by hydraulic control.

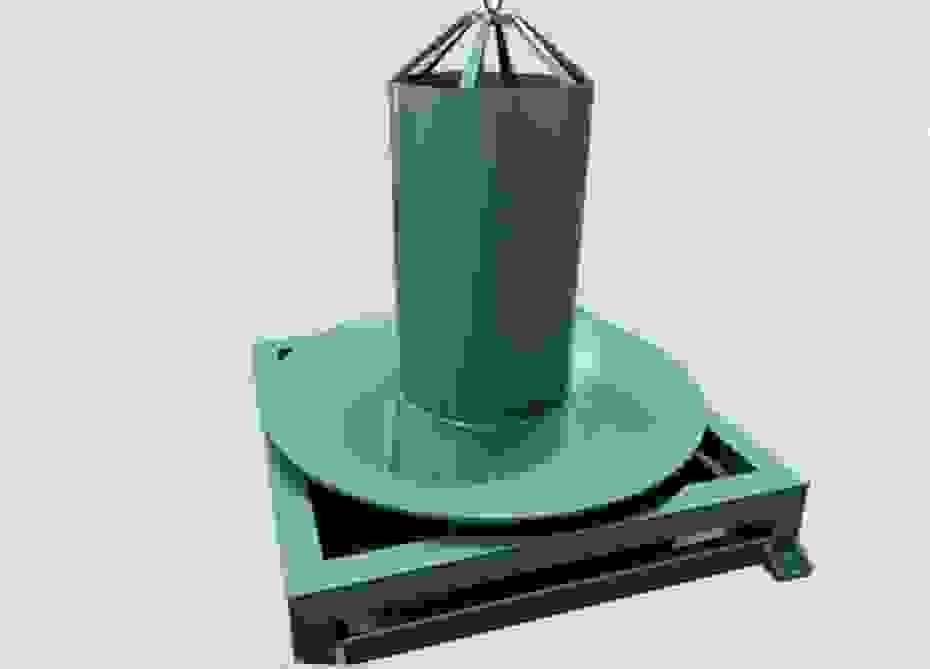

Pay-offs Coil Openen

The uncoiler is generally a metal structure frame for

shelving large-sized billets (12mm-40mm) for coiling. The

treated wire is placed on the wire feeder of the wire feeder, and

the wire can be straightened by the active pressure roller on

the wire splitting bracket, and the wire can be sent clockwise

through the active pressure roller operation button. Imported

straightening machine.

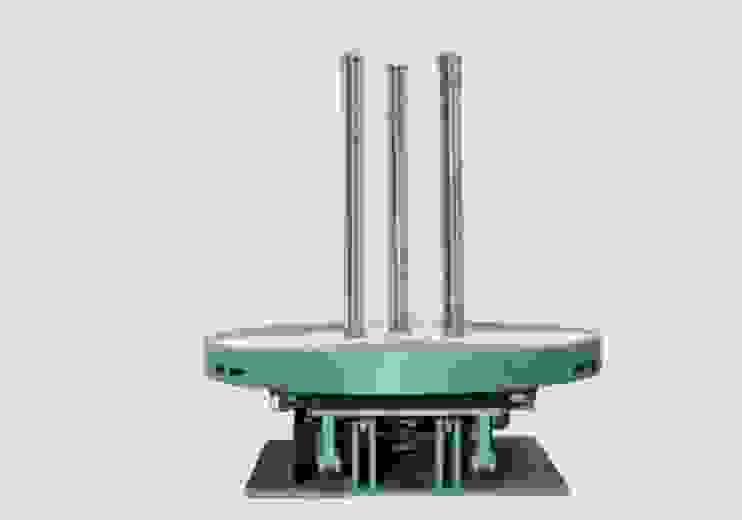

Double tray loading rack

The pay-off reel is a metal structure frame for laying blank coils,

and it adopts double-disc dumping type feeding. It is mainly composed

of 1 rotating base and 2 tilting racks (hereinafter referred to as disc

material racks). The coil rack is used to place the blank coils. When the

equipment runs and pulls out the coil material from one of the coil racks,

the coil rack automatically rotates, so that the blank coil can be pulled

out smoothly without causing any damage. .When the blanks in one round rack are drawn, the other round

rack is rotated through the rotating base to continue the work. The coiledmaterial rack that has been drawn can be automatically dumped at 90

degrees to install the next circle of coiled material and wait for it to be

used alternately. Reduce the waiting time for loading.

Active pay-off reel

The active pay-off reel is a metal structure frame for laying blank

coils. The equipment adopts dump feeding, manual diameter adjustment

of inner guide post, and increase of tension adjustment mechanism,

which can automatically adjust the rotation speed according to the

drawing speed of the main machine and the inner and outer circles of

the wire blank, so that the payoff speed matches the drawing. In the

event of an emergency stop of the host, the pay-off reel automatically

brakes to stop pay-off. Automatically pour 90 degrees when loading.

- 立即下载你可以在这按钮上添加一个链接,或上传一个文档!