Provide you with excellent equipment solutions

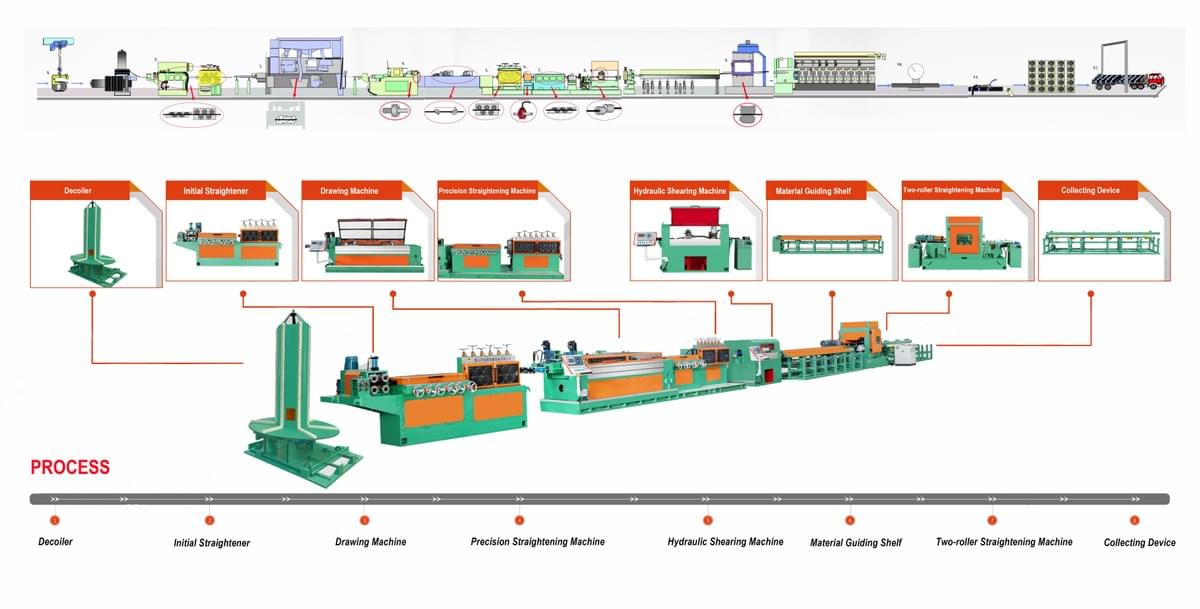

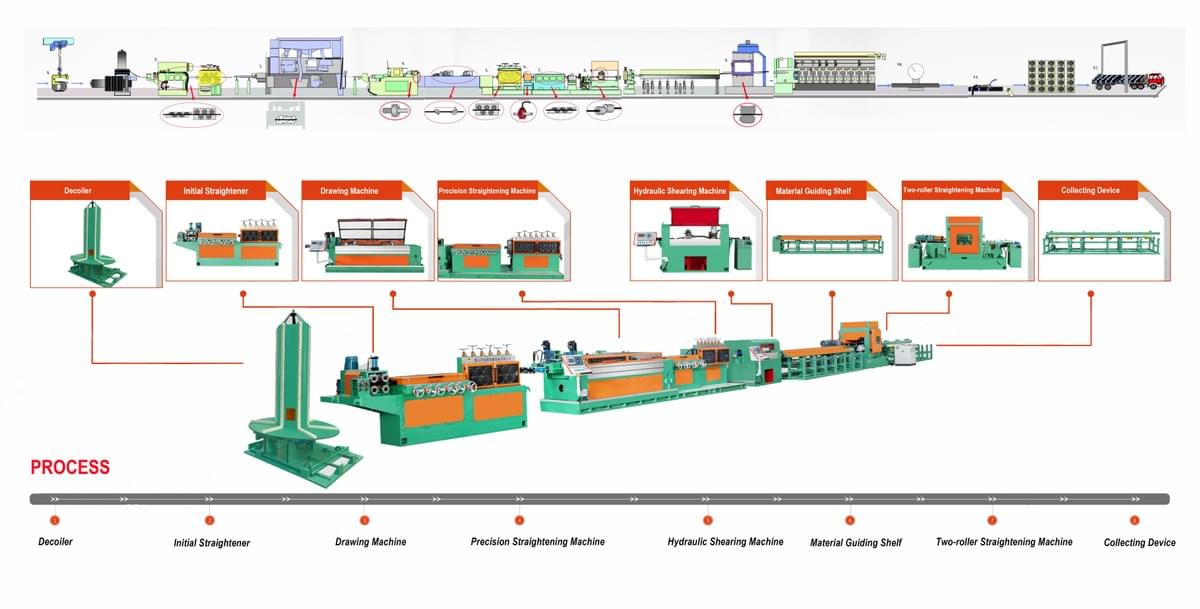

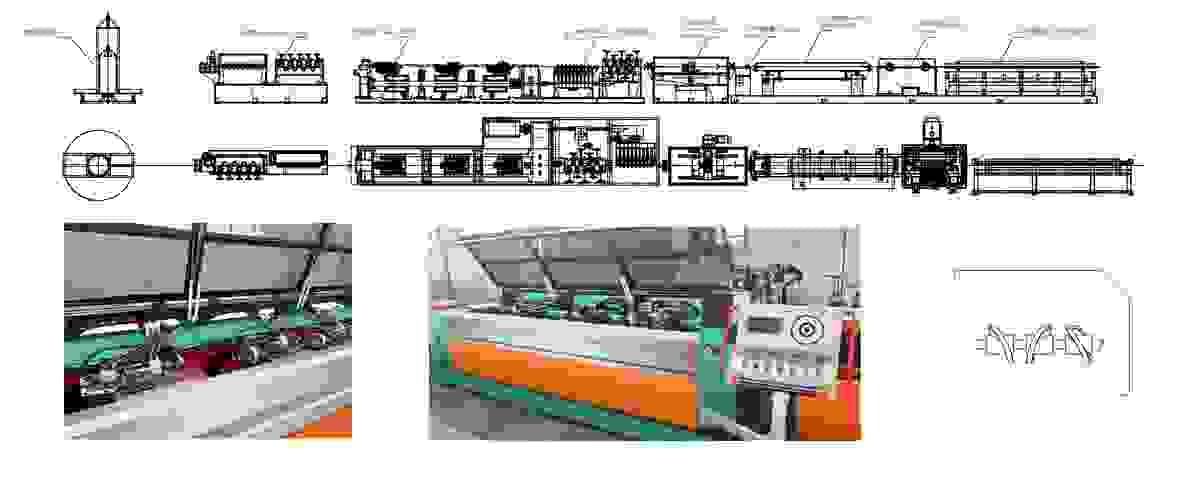

The combined continuous drawing unit is a special equipment that can produce cold-drawn profiles of different shapes and specifications.It is a combined unit that integrates the processes of billet opening, initial straightening,drawing and finished product straightening,fixed-length shearing,polishing,and collection.

Combined drawing unit production line

The combined continuous drawing unit is a special equipment that can produce cold-drawn profiles of different shapes and specifications. It is a combined unit that integrates the processes of billet opening, initial straightening, drawing and finished product straightening, fixed-length shearing, polishing, and collection.

LHJZ continuous drawing unit is a high-efficiency, professional processing equipment for metal bars and pipelines. The unit has the functions of uncoiling, initial straightening, stretching, fine straightening, cutting to length, feeding, polishing, and collection of finished products. It can process multiple processes in one, and can process a variety of special-shaped materials, such as hexagonal, square, flat square, round and other profiles. The stretching mechanism of this unit can also be divided into double cam or triple cam structure. The triple cam structure is that the stretching mechanism has three drawing trolleys that run alternately during stretching. Longer life.

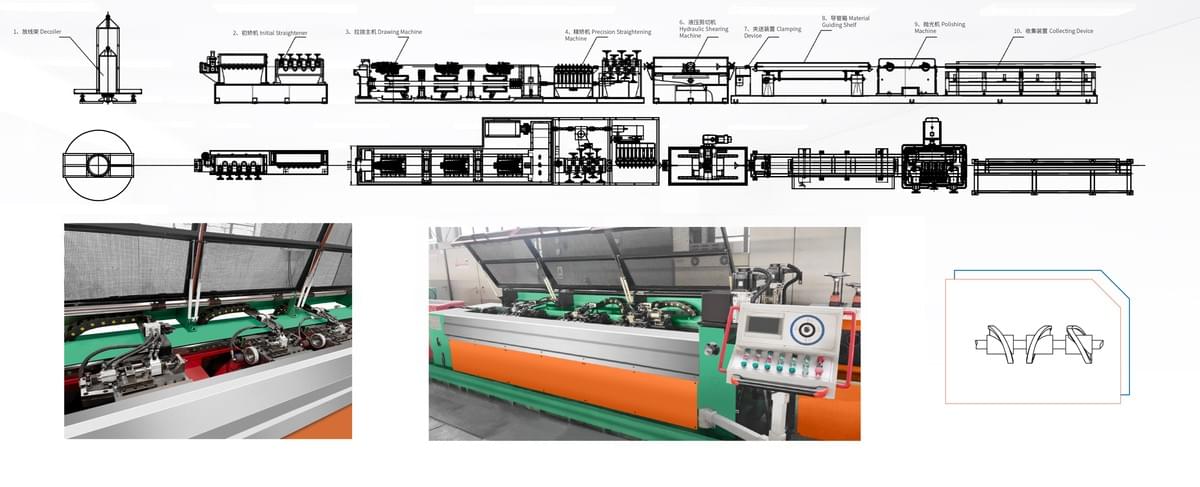

Combined Drawing Machine (three cam CNC hydraulic shears)

Combined continuous drawing unit is capable of producingdifferent shapes, a variety of cold-drawn profile specificationsof special equipment. Is a set of

open blank volume, initialstraightening, drawn and finished fine straightening, fixedlength cutting, polishing, collecting and other processes inone combined unit.This unit has three sets in tension whenpulling the car run alternately.

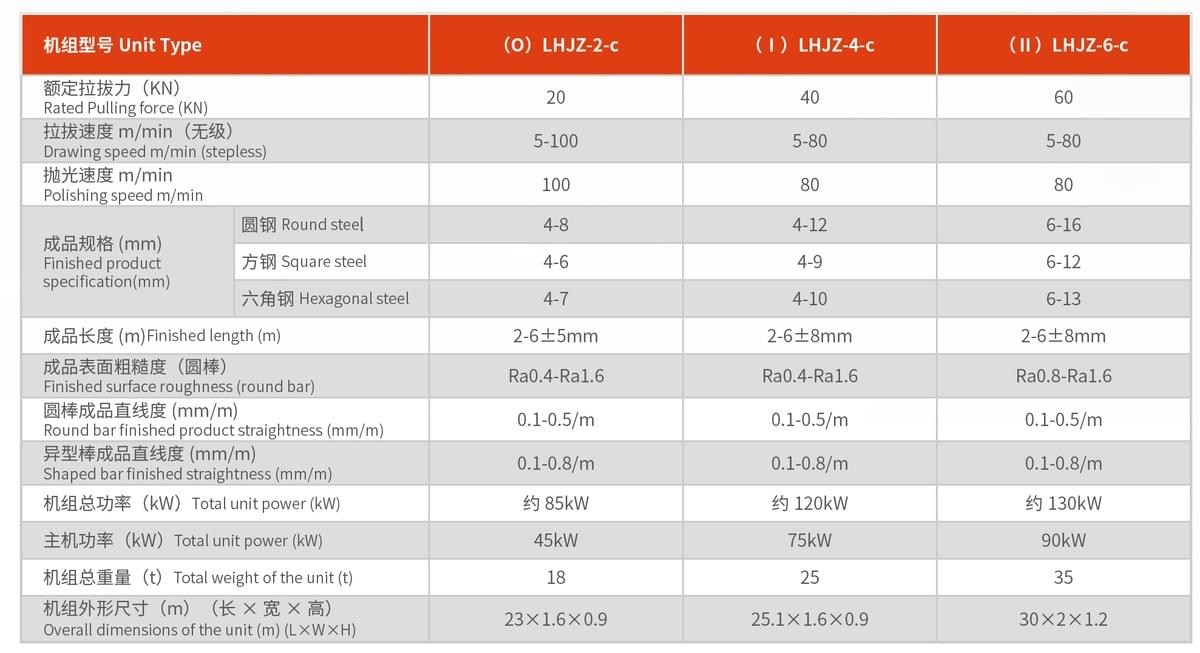

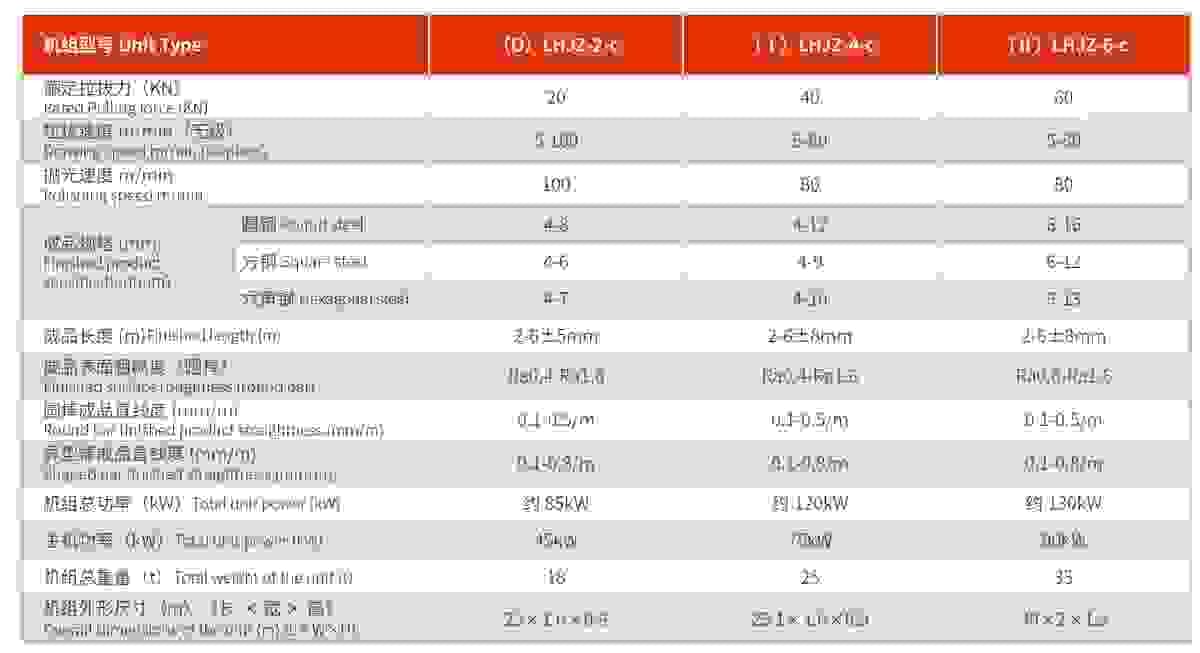

TECHNICAL PARAMETER

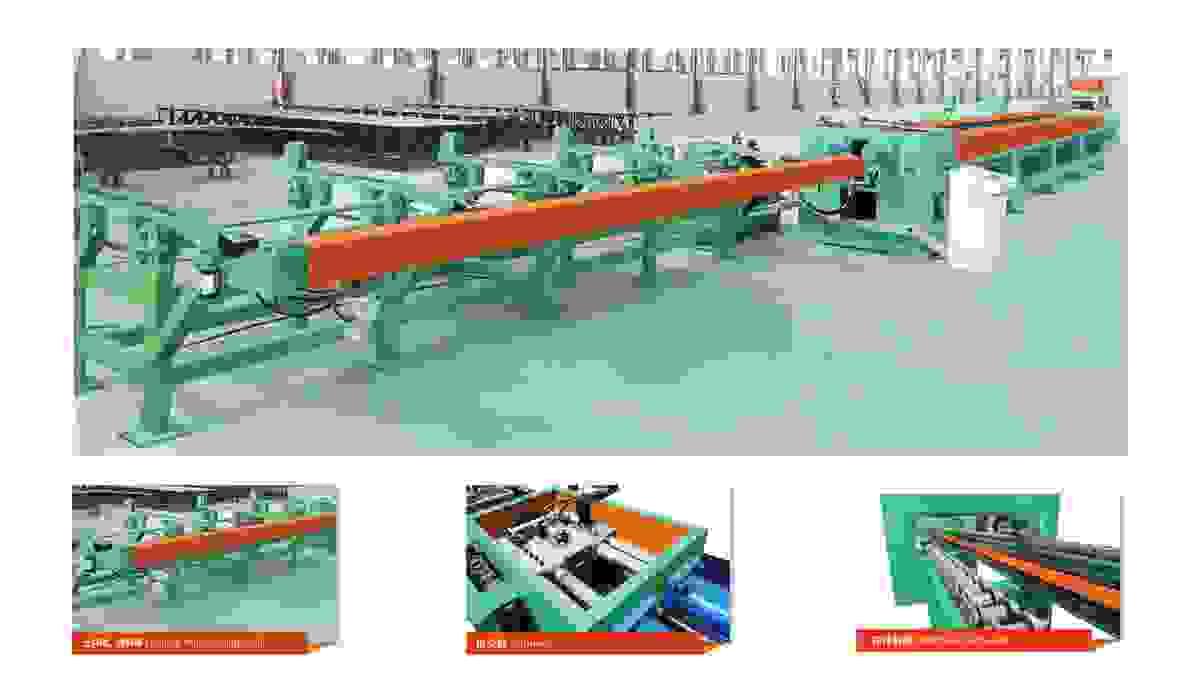

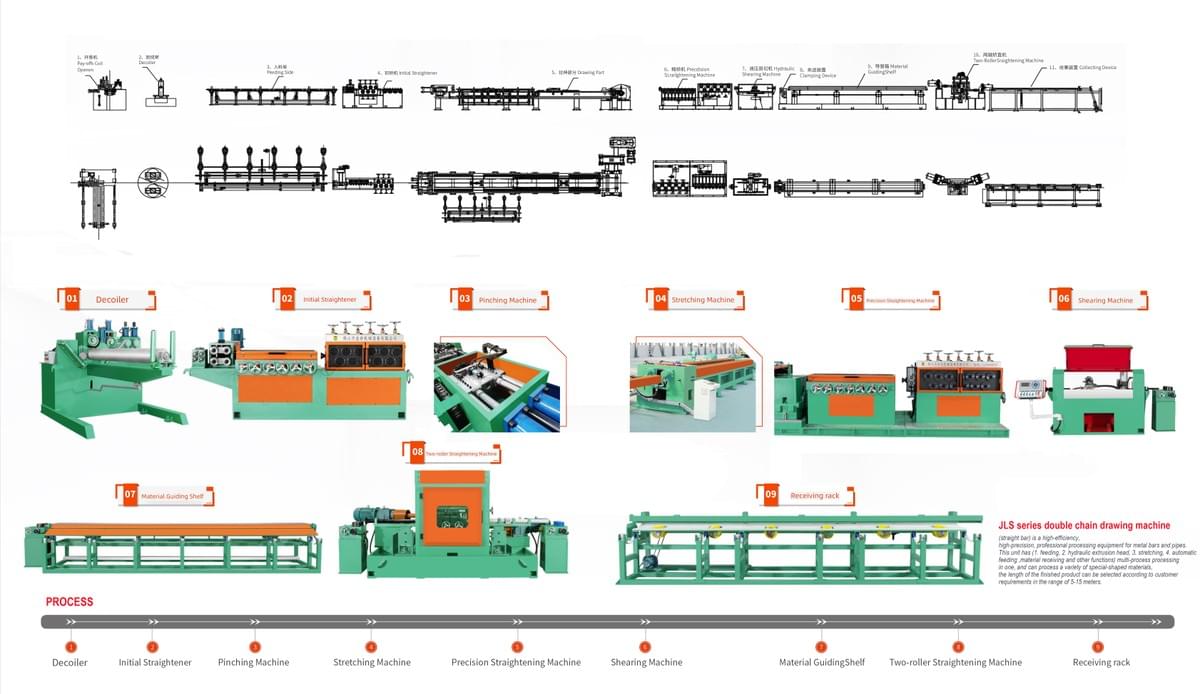

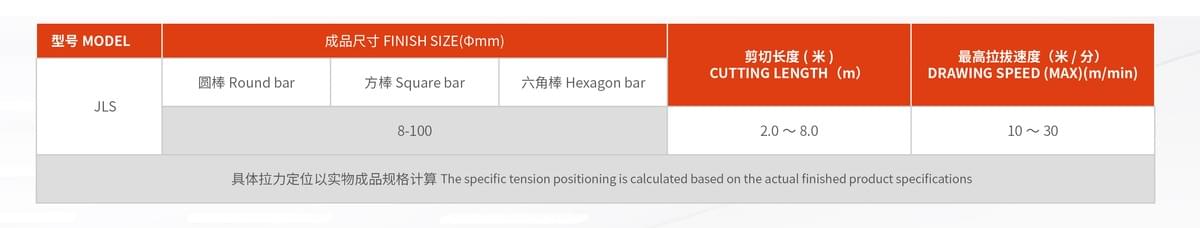

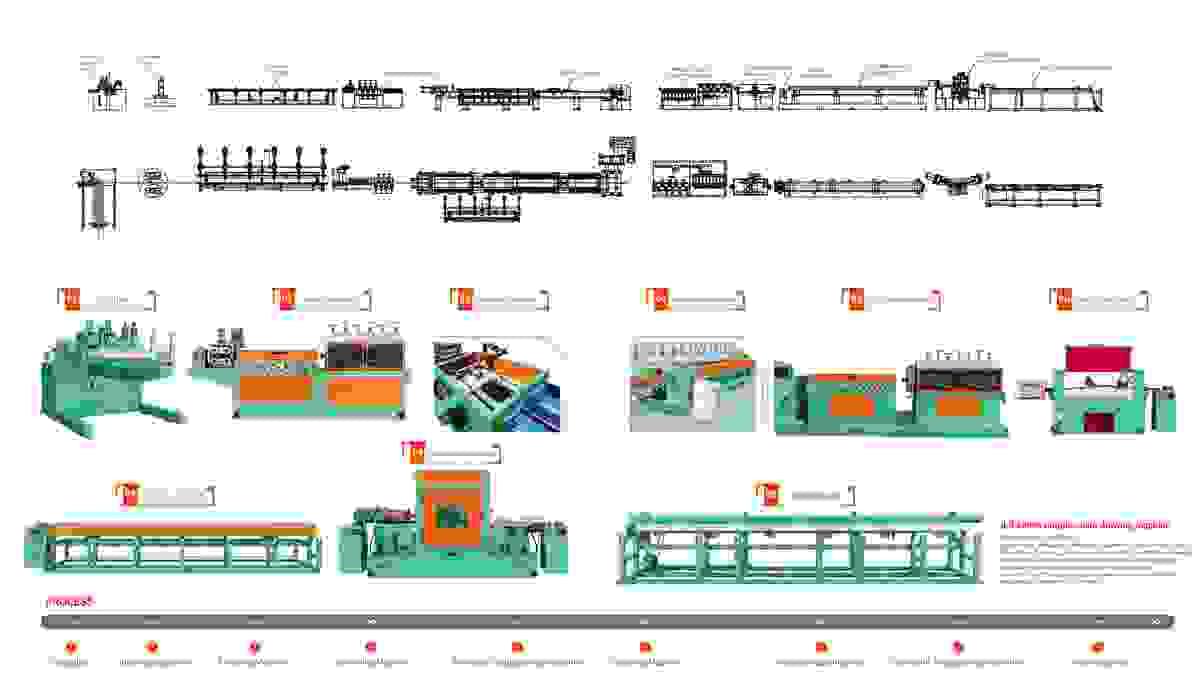

Double Chain drawing unit

Double chain double drawing machine is a high-efficiency, high-precision, professional processing equipment for metal rods and pipes. This unit has the functions of feeding, hydraulic extrusion, stretching, straightening, Fixed length cutting, polishing, finished product aggregate and other functions, and can process a variety of special-shaped materials, the length of the finished product can be selected according to customer requirements in the range of 5-15 meters. And this machine can also be divided into a group of drawing trolleys and two groups of drawing trolley structures. The two groups of drawing trolley structures can alternately draw metal wires, which can achieve high-speed continuous drawing and more stable performance.

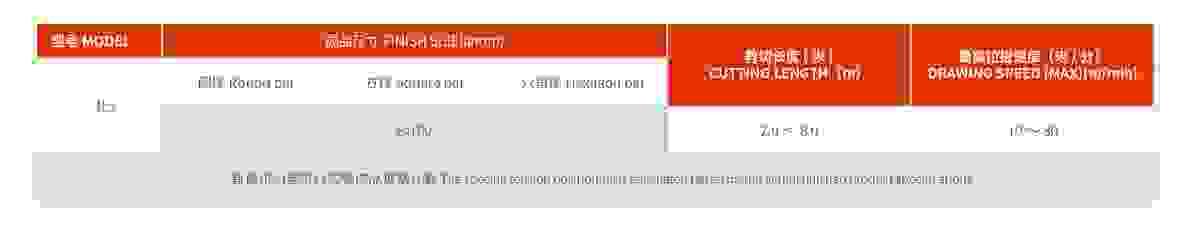

TECHNICAL PARAMETER

Double chain double drawing machine is a high-efficiency, high-precision, professional processing equipment for metal rods and pipes. This unit has the functions of feeding, hydraulic extrusion, stretching, straightening, Fixed length cutting, polishing, finished product aggregate and other functions, and can process a variety of special-shaped materials, the length of the finished product can be selected according to customer requirements in the range of 5-15 meters. And this machine can also be divided into a group of drawing trolleys and two groups of drawing trolley structures. The two groups of drawing trolley structures can alternately draw metal wires, which can achieve high-speed continuous drawing and more stable performance.

Duplexes drawing machine (straight bars)

JLS series double chain drawing machine (straight bar) is a high-efficiency, high-precision, professional processing equipment for metal bars and pipes. This unit has (1. feeding, 2. hydraulic extrusion head, 3. stretching, 4. automatic feeding , material receiving and other functions) multi-process processing in one, and can process a variety of special-shaped materials, the length of the finished product can be selected according to customer requirements in the range of 5-15 meters.