The company offers a diverse range of premium quality products.

The company offers direct sales, ensuring high-quality products and services with a strong commitment to business integrity and extensive production experience.

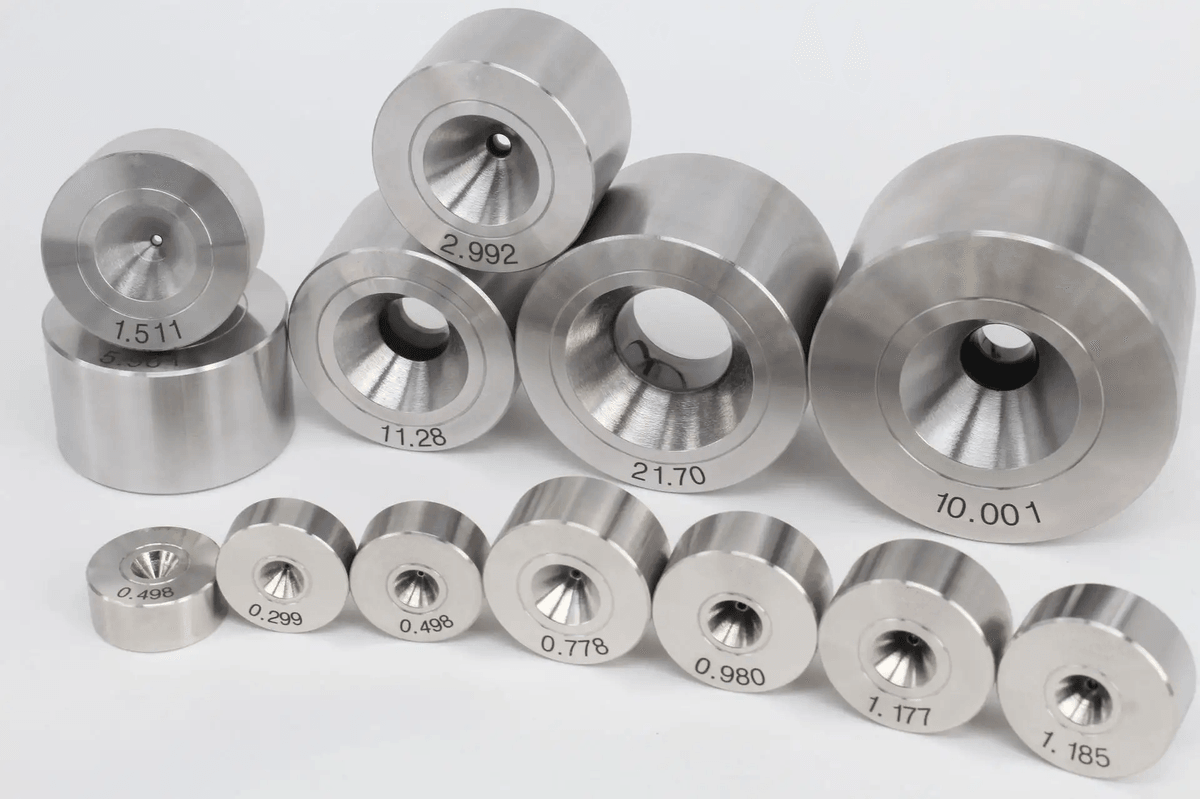

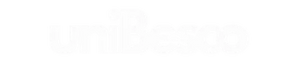

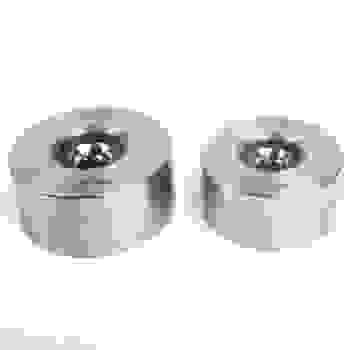

Diamond Wire Drawing Die

Natural diamond, abbreviated as ND, is formed naturally in the high temperature and high pressure environment of the earth’s crust. Due to its extremely rigid and hard crystal structure, boron or nitrogen impurities may be incorporated during the formation process. The natural diamonds selected by Yudi Mould are rigorously screened to ensure their purity.

Advantages:

· Among all core materials, natural diamond has the best surface finish.

· Extremely high hardness and wear resistance ensure the die’s service life.

· Among all core materials, natural diamond has the highest thermal conductivity, suitable for high-temperature processing.

· Natural diamond can withstand temperatures up to 1700℃.

· Easy to adjust, smooth wire drawing process.

Application:

Natural diamond dies are mainly used for fine wire and ultra-fine wire drawing, or in applications that require excellent wire surface finish and good heat dissipation.

· Tungsten wire, molybdenum wire

· Precious metal wires

· Semiconductor alloy wires (gold wire, copper wire, silver-plated copper wire, aluminum wire, silver alloy wire, etc.)

· Stainless steel wires (304 wire, 316L wire, 430 wire, 201 wire, 202 wire, etc.)

· Copper wires (pure copper wire, silver-copper alloy wire, aluminum-copper alloy wire, brass wire, copper-clad aluminum wire, etc.)

· Steel wires (Saw steel wire, spring steel wire, tire-plated copper steel wire, etc.)

· Special alloy wires (copper-nickel alloy wire, nickel-chromium alloy wire, etc.)