Professional wire drawing dies manufacturer

The company offers direct sales, ensuring high-quality products and services with a strong commitment to business integrity and extensive production experience.

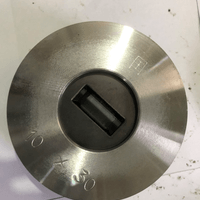

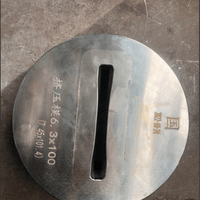

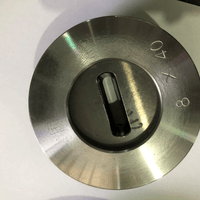

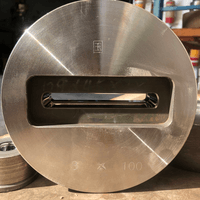

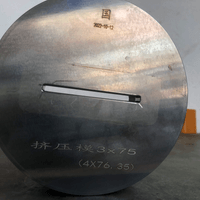

COPPER EXTRUSION DIE/COPPER DRAWING DIE

Copper die has wear resistance. High bending strength. Strong impact resistance, inner hole up to mirror finish, the surface of the stretched product bright and clean, suitable for copper, iron, aluminum, zinc, stainless steel and other metals extrusion. High hardness, high wear resistance, tungsten steel has the advantages of high hardness (HRC89), good wear resistance, wear resistance than die steel. No strain on the surface of the machined parts, compared with the steel mold, the advantage is good thermal conductivity, non-stick mold, can ensure that the temperature distribution of the mold in the work is uniform, will not crack the mold due to local high temperature, will not make the stretched product appear cold sweat, demarking, wrinkling phenomenon, significantly improve the product surface quality. Economical and practical, mold service life is long, the life of tungsten steel is 5-10 times longer than the steel mold, economic and practical. Simplified processing process, compared with the steel mold does not require heat treatment directly polishing, so reduce the heat treatment cost, shorten the mold processing time, can be used to draw the mold can reduce the number of drawing, reduce the mold cost.