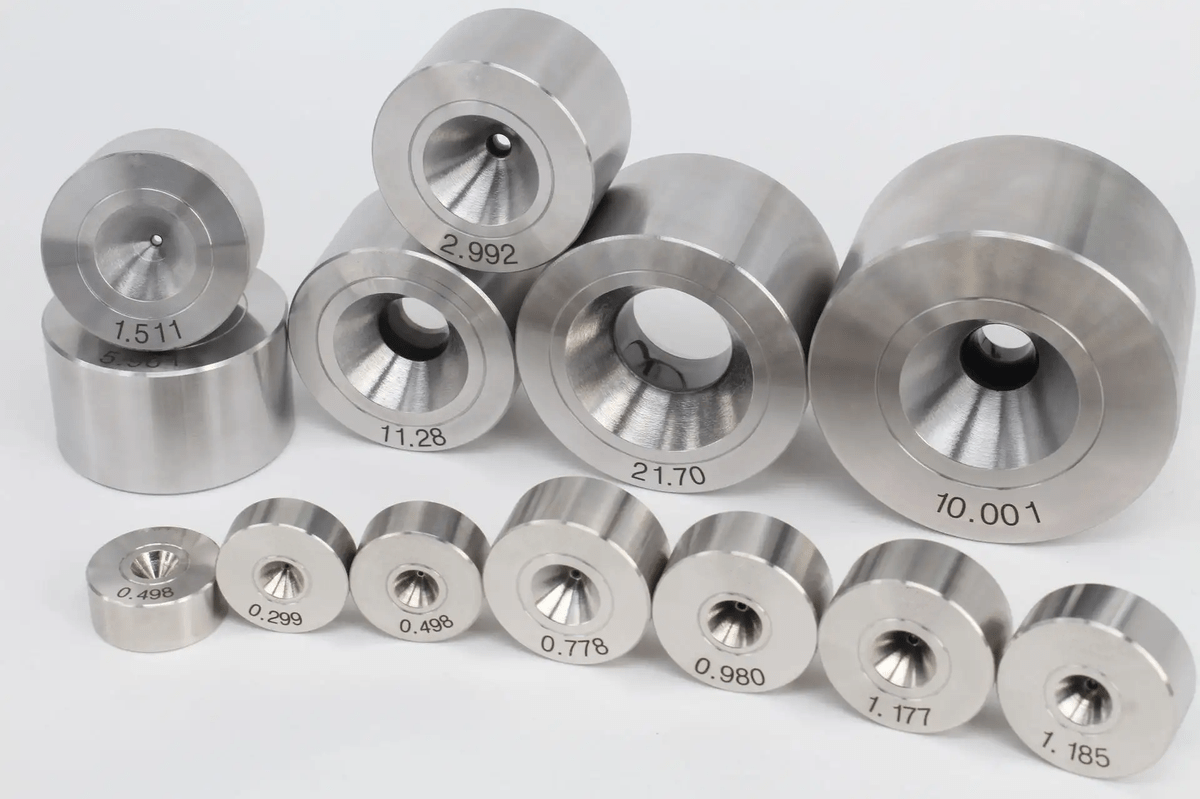

Manufacturing steps of cemented carbide wire drawing die:1. Mold blank processing

The mold base must be cylindrically ground, using a special fixture on a grinder and grinding with a diamond grinding wheel.

2. Interference amount of mounting

1) In order to obtain a certain prestress for the mold core during assembly, the inner hole diameter of the mold sleeve must be smaller than the outer diameter of the mold core. The difference between the two is called interference.

2) The amount of interference should be determined based on the size and deviation of the mold core, the drawing stress and the inserting method. The actual interference amount when the mold is installed.

3) The die set is equipped with two methods: hot pressing and cold pressing. The cold pressing method is mostly used to manufacture wire drawing dies with smaller specifications and for drawing soft metals.

3. Mold set processing

The mold sleeve is formed by lathe turning. The control points during processing are as follows:

1) The inner diameter roughness of the mold sleeve must reach 0.80 to 1.6m, which is conducive to close cooperation with the mold sleeve;

2) The inner diameter of the mold sleeve should correspond one-to-one with the outer diameter of the mold base to ensure that the interference of each mold is accurate;

3) The bottom surface of the inner hole of the mold sleeve must be parallel to the outer end of the mold, and ensure that it is perpendicular to the center line of the mold hole after installation;

4) The ovality of the inner hole of the mold sleeve should be as small as possible and should not be greater than 0.02mm. During hot mounting, the outer surface of the mold sleeve should be polished to ensure even cooling after mounting.

4. Mounting technology

The cold pressing mounting process is to press the mold blank into the mold sleeve with a press at room temperature.